Basf will be Iveco Group’s prime partner for electric vehicle battery recycling

A global chemical giant for battery chemistry and recycling. Iveco Group, in fact, has chosen Basf as its first partner for recycling electric vehicle lithium-ion batteries. This step is part of Iveco Group’s circular economy strategy, which follows the framework of the 4Rs – Repair, Refurbish, Repurpose and Recycling – to increase the lifespan of […]

A global chemical giant for battery chemistry and recycling. Iveco Group, in fact, has chosen Basf as its first partner for recycling electric vehicle lithium-ion batteries.

This step is part of Iveco Group’s circular economy strategy, which follows the framework of the 4Rs – Repair, Refurbish, Repurpose and Recycling – to increase the lifespan of batteries while reducing their overall environmental impact.

In recent months, Iveco Group’s powertrain division, FPT Industrial, had entered into an agreement with startup Reefilla to launch a pilot project to give a second life to electric commercial vehicle batteries, specifically the eBS37 model installed in the Iveco eDaily.

Potrebbe interessarti

FPT Industrial – Reefilla: a cooperation to re-use batteries for mobile charging services

Battery recycling, the Iveco-Basf axis

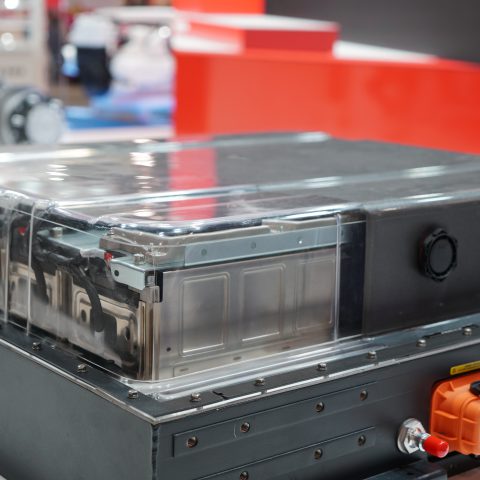

BASF recently opened in Schwarzheide, Germany, Europe’s first production and recycling center for battery materials. The company will organize and manage the entire recycling process for lithium-ion batteries used in Iveco-branded electric vans, buses and trucks. The agreement provides for the collection, packaging, transportation and recycling of batteries in various European countries. After collection, Basf will mechanically process the batteries into black mass, from which essential raw materials-such as nickel, cobalt, and lithium-can be extracted and recovered for use in the production of new batteries.

«Life cycle thinking is one of our strategic sustainability priorities. Basf shares this approach with us, and its extensive battery collection network and recycling capabilities in Europe will help us close the loop from end-of-life batteries to new ones. Working together, we will be able to achieve a circular economy and reduce our carbon footprint, fully in line with the Group’s commitment to achieve zero carbon emissions by 2040», commented Angela Qu, Chief Supply Chain Officer of Iveco Group.

«The partnership with Iveco Group is our first battery recycling agreement for electric vans, buses and trucks and represents an important step for our battery recycling business, allowing us to expand our activities in the commercial vehicle sector,” “It will enable us to further strengthen our European collection network and make further progress in this developing market. With our recycling solutions, we aim to support the European market to close the loop and meet the ambitious circular economy-focused policy requirements of the EU Battery Regulation», said Daniel Schönfelder, president of Basf’s Catalysts division, who is also responsible for the company’s battery materials and battery recycling activities.