BRIST has launched a corner drive e-axle for zero emission LF buses (intercity included)

Axles supplier BRIST has been exhibiting its brand new low floor electric bus e-axle technology eCOR225 LF at ACT Expo in Las Vegas and Busworld Turkey together with Schaeffler 800V hairpin motors. The new product joins a family of solution highly dedicated to the zero emission commercial vehicles market. The company, based close to Brescia in Italy, has been well-known […]

Axles supplier BRIST has been exhibiting its brand new low floor electric bus e-axle technology eCOR225 LF at ACT Expo in Las Vegas and Busworld Turkey together with Schaeffler 800V hairpin motors. The new product joins a family of solution highly dedicated to the zero emission commercial vehicles market.

The company, based close to Brescia in Italy, has been well-known in minibus, midibus and BRT segment, and now is expanding its e-mobility portfolio into full-size bus segment including city and intercity buses. Their references include well-known EV manufacturers such as Hyundai, Alexander Dennis (NFI Group), Karsan, Anadolu Isuzu, Arrival and CRRC.

At Busworld Europe 2023 in Brussels they unveiled their own Corner e-Drive electric axle, aimed at increasing the efficiency, balance and structure of electric vehicles.

Focus on BRIST eCOR225 LF

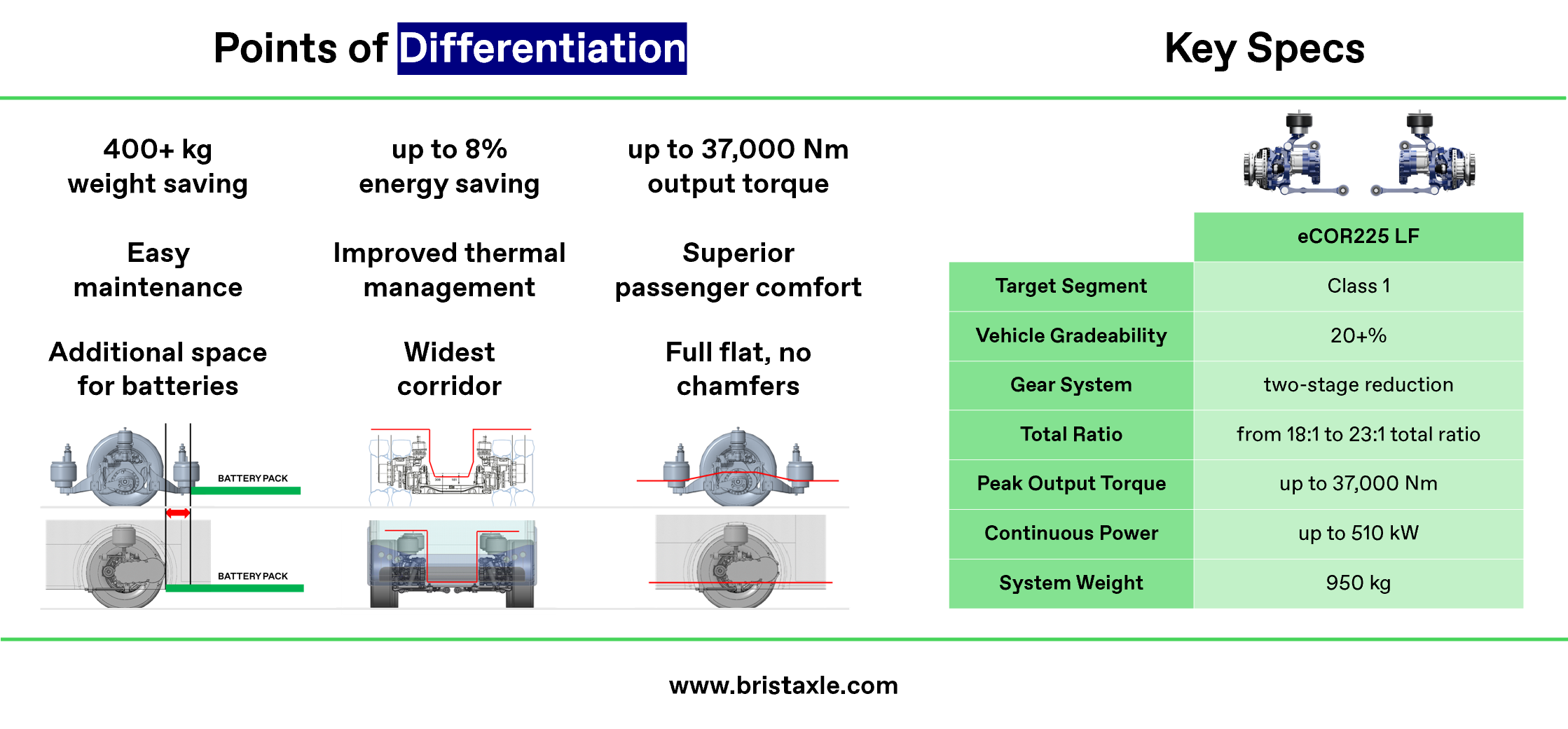

The latest news from BRIST, namely the corner drive e-axle eCOR225 LF, features large and ventilated areas dedicated to the e-motor tackling thermal behaviour challenges of electric axles. The patented design is innovative but simple, aiming to be both reliable and competitive. Individual access to the electric motor and gears is easily allowed. Compared to e-portal concept, the corner drive e-axle layout enables 400+ kg savings in total weight, while energy savings are mentioned to be in the range between 2 and 8%.

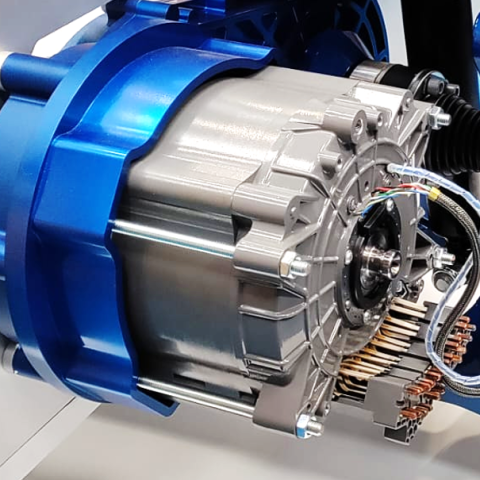

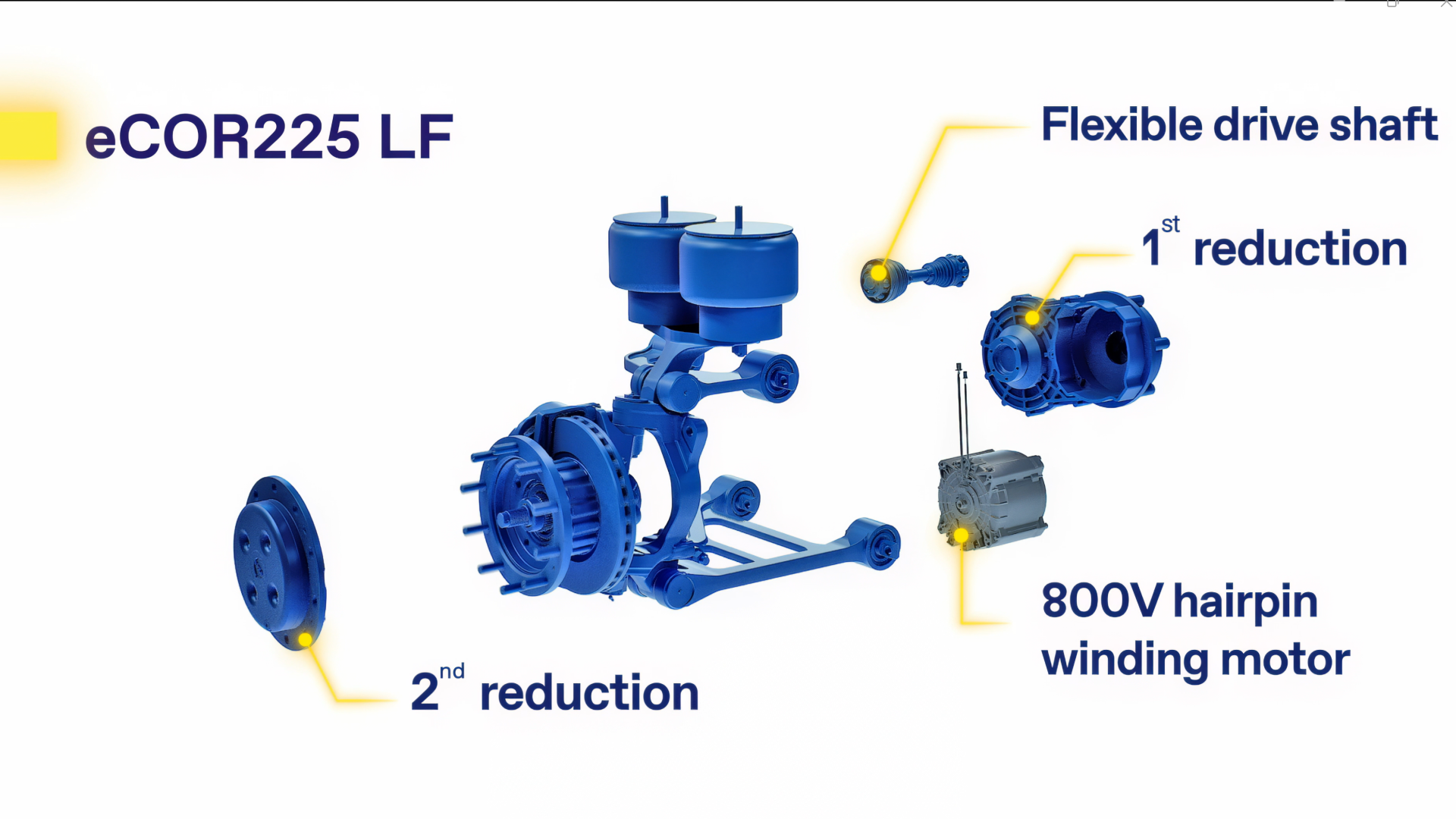

The heart of the system is the 800V hairpin winding motor directly mounted to the chassis, therefore avoiding road vibrations. Torque output can get up to 37,000 Nm at wheel, while continuous output is up to 510 kW.

It should be mentioned that BRIST has “adapted off-the-shelf motor & inverter of leading electronics brands to the Corner Drive Family to leverage being ‘proven’ & ‘cost competitive’ – as BRIST Managing Director Güngör Oduncu points out -. These motors are used in truck segment and hence, very cost competitive and durable. Taking the advantage of being flexible in design, dedicated variants are generated to meet specific market requirement such as local content (e.g. South America, North America), high gradeability, high speed and narrower vehicle width.”

The motor goes along with a flexible drive shaft and two reductions. All the components are ‘packed’ in the wheel arch area providing larger space for battery packing. BRIST’s technology offers a high degree of flexibility (width of bus corridor can be adjusted according to OEM’s needs) and makes possible to have a fully low floor design for the entire length of the bus.