How to make the most of a battery capacity and still be able to monetize it for second life?

This final piece underlines the critical role of battery analytics in effectively navigating the complexities of monitoring battery degradation, conducting safety audits, and evaluating the eligibility of batteries for second-life applications.

Authored and sponsored by PowerUp.

It follows two contributions on “Unleashing value with battery analytics in the mobility revolution“ and “Unleash the potential of your eBuses batteries“.

Source of opening picture: Daimler Truck AG

In the culmination of our series on advanced battery analytics for electric bus operations, it is time to take on the second-life management topic. This final piece underlines the critical role of battery analytics in effectively navigating the complexities of monitoring battery degradation, conducting safety audits, and evaluating the eligibility of batteries for second-life applications.

Over the past decade, the electric car market has witnessed a steady growth, coinciding with the average lifespan of batteries, which is also around 10 years. While two-thirds of a battery’s environmental footprint occurs during the phases of production and end-of-life, it is imperative to discuss ‘lifespans’ in the plural to extend their usage and fulfill the promises of impact reduction.

To postpone the inevitable moment of recycling and surpass the production/destruction paradigm, the option of reuse must be considered at its true value. This approach demands a more enlightened management of the first life of batteries and appropriate redirection in their second life.

How to make the most of a battery capacity and still be able to monetize it for second life?

Are second-life batteries safe and reliable enough to be used?

When batteries reach around 80% of their capacity, they are typically considered ‘end of life’ for their initial use. However, these batteries often remain suitable for other applications, marking the beginning of their second life. Numerous solutions for their reuse are already in development, with Battery Energy Storage Systems (BESS) projects increasingly incorporating electric bus or other EV batteries. Unlike electric vehicles, BESS projects benefit from fewer space or weight limitations, allowing for the stacking of hundreds of battery packs or racks to store energy.

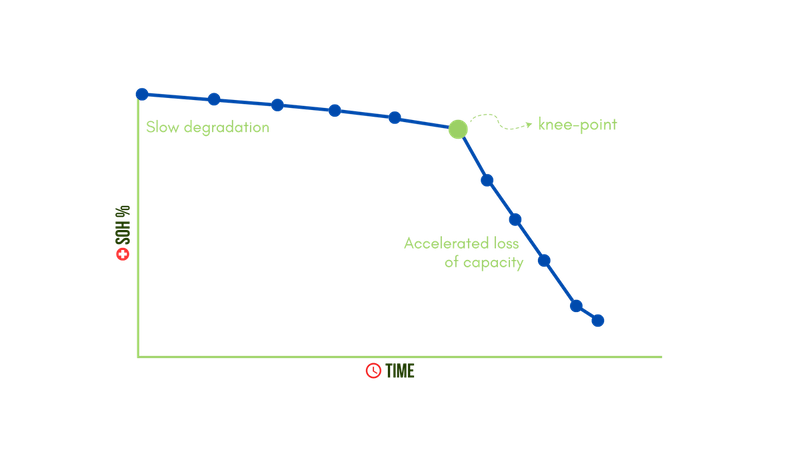

1. Prevent knee-point

Even though it is dependent on usage, batteries typically degrade slowly in the first part of their life: batteries usually lose only a few percents of their capacity in their first years of operation.

However, aging is a nonlinear phenomenon: at some point, the trend drastically changes, and a steep drop of SOH can be witnessed in a limited time window (several percents in a few weeks). This trend change is called a knee-point (see figure 1), and this brutal acceleration of the capacity loss can precipitate the need of maintenance, or even paralyze a whole system if not detected early on.

But how to determine the right time to put an end to battery pack usage and monetize it for second life? Understanding the nuances of battery degradation is first paramount to detect knee-point stage and optimize second life management. Battery analytics, armed with the ability to analyze usage profiles and chemistry specifics, play a crucial role in finely monitoring battery degradation and predicting batteries lifetime of batteries. This proactive approach allows for strategic decision-making, ensuring that batteries are repurposed at the right time and at the right price.

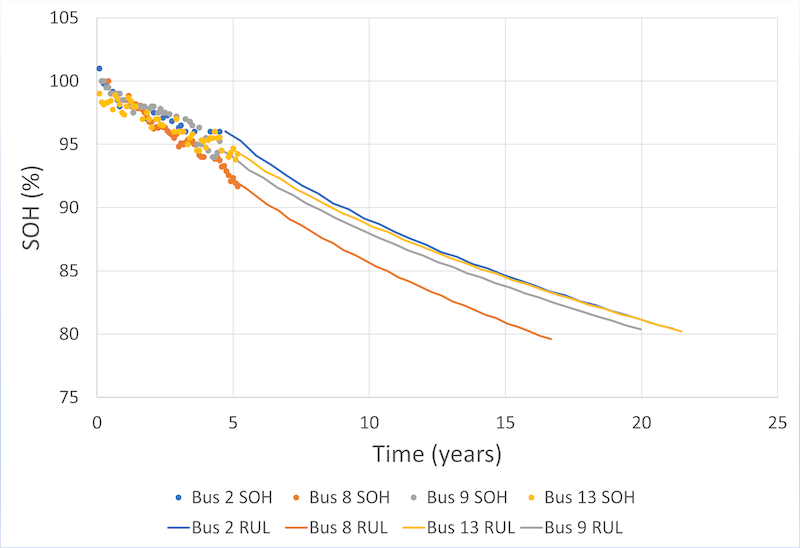

2. Estimate the best price

Examining a real use-case involving 4 electric buses with LFP 258 kWh batteries, monitored by PowerUp for five years, reveals a degradation of 6 to 8% of their SOH. These batteries are estimated to reach their End of Life (EoL) starting from year 17 for the less performing and year 22 for the most performing.

Combining Remaining Useful Life (RUL) predictions with knee-point detection allows fleet managers to determine the optimal time to sell batteries. Companies like Cling Systems or Circunomics can also perform estimations of battery value based on demand, price per kWh, and the critical variable of SOH at specific dates.

3. Ensure the safety

The qualification of batteries for a second life is contingent upon a meticulous safety audit. Battery Management Systems (BMS) latest collected data is not enough as it may overlook certain issues such as lithium plating formation or advanced cell imbalances. Once again, battery analytics step in as the vigilant eye, pinpointing potential safety concerns that might have been missed. This ensures that only batteries meeting stringent safety criteria move forward into their second life.

Conclusion

As we conclude our exploration into advanced battery analytics for electric bus operations, the spotlight on second-life management reveals a landscape where predictive insights, safety audits, and market-driven estimations converge.

Battery analytics emerge as indispensable tools, shaping the future of sustainable energy storage. Through a holistic approach, we pave the way for a robust second life for electric bus batteries, proving that their value extends far beyond their initial deployment.