Hübner presents a hydropneumatic suspension at Busworld

“Electric buses have greater range and run more smoothly using chassis systems without compressed”. This is the opinion of Hübner group, that is going to unveil at Busworld Europe in Brussels a hydropneumatic suspension and damping system for chassis without compressed air that provides more driving comfort. According to the supplier, through the operation of […]

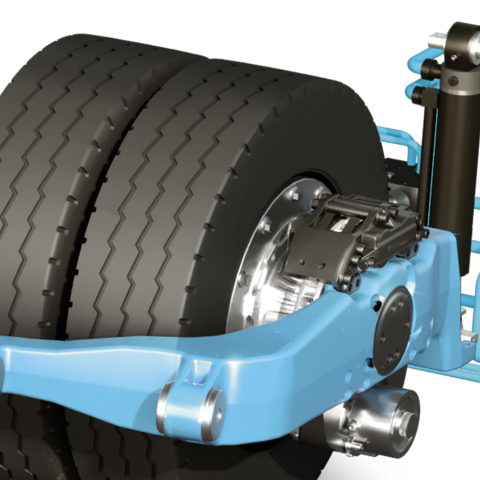

“Electric buses have greater range and run more smoothly using chassis systems without compressed”. This is the opinion of Hübner group, that is going to unveil at Busworld Europe in Brussels a hydropneumatic suspension and damping system for chassis without compressed air that provides more driving comfort.

According to the supplier, through the operation of the compressor, two thirds of the energy escapes. At the end of a typical lifting and lowering operation with compressed air, for example at a bus stop, more than 80 percent of the used energy is lost.

Hemscheidt Fahrwerktechnik, part of Hübner group, has developed the new hydropneumatic suspension and damping system.

Hübner hydropneumatic suspension on the launching pad

“Compressed air is a real energy drain for the suspension and damping of the vehicle chassis. On top of that, it takes up too much space,” explains Dr. Mark Wöhrmann, Managing Director of Hemscheidt Fahrwerktechnik GmbH & Co. KG. “A better alternative makes use of oil as the hydraulic fluid for a hydropneumatic suspension and damping. Our system gives a high degree of comfort and stability – even on uneven road surfaces. In addition, there is significantly higher energy efficiency than with compressed air. This is because the oil in the closed hydropneumatic suspension and damping system from Hemscheidt Fahrwerktechnik is continually reused as the hydraulic fluid”.

“By the end of this year, we want to begin test operations with prototypes so that we will be able to supply the first customers with the hydropneumatic suspension and damping systems starting in 2024,” says Dr. Mark Wöhrmann.

Rainer Eickhoff, Head of Sales and Project Management at Hemscheidt Fahrwerktechnik, explains: “Our hydropneumatic suspension and damping system conserves the battery capacities of electric buses and gives the vehicles a longer running time. Using oil as a hydraulic fluid in the chassis, e-buses have a significantly further range, which is crucial for economical and efficient operation, especially in local public transport.”

Currently, Hemscheidt Fahrwerktechnik is planning two variants of the new system: in the stand-alone system, the motor of the oil pump is controlled by a higher-level control unit. There is also an alternative: “Because a central pump is easy to integrate in existing vehicle concepts, in this way we can make it possible for transit companies to convert their current vehicles to e-mobility,” explains Rainer Eickhof”