JOST BusLink: on a mission to enhancing articulated buses

Authored and sponsored by JOST Articulated buses are a feature of many cities around the world. They are used on routes with high passenger numbers and are the only solution for cities without urban rail transport or with mountainous topography. The manufacturing of articulated buses is demanding due to the required driving stability in the […]

Authored and sponsored by JOST

Articulated buses are a feature of many cities around the world. They are used on routes with high passenger numbers and are the only solution for cities without urban rail transport or with mountainous topography. The manufacturing of articulated buses is demanding due to the required driving stability in the area of the articulation, especially with technological innovations such as the electric or hydrogen bus.

JOST provides a solution for this: the new articulation pusher bus system BusLink, launched at Busworld Europe in late 2023, efficiently and safely regulates the transmission of the thrust force from the rear vehicle to the front vehicle.

BusLink is an articulated bus system that can be customised and is particularly suitable for the requirements of electric buses.

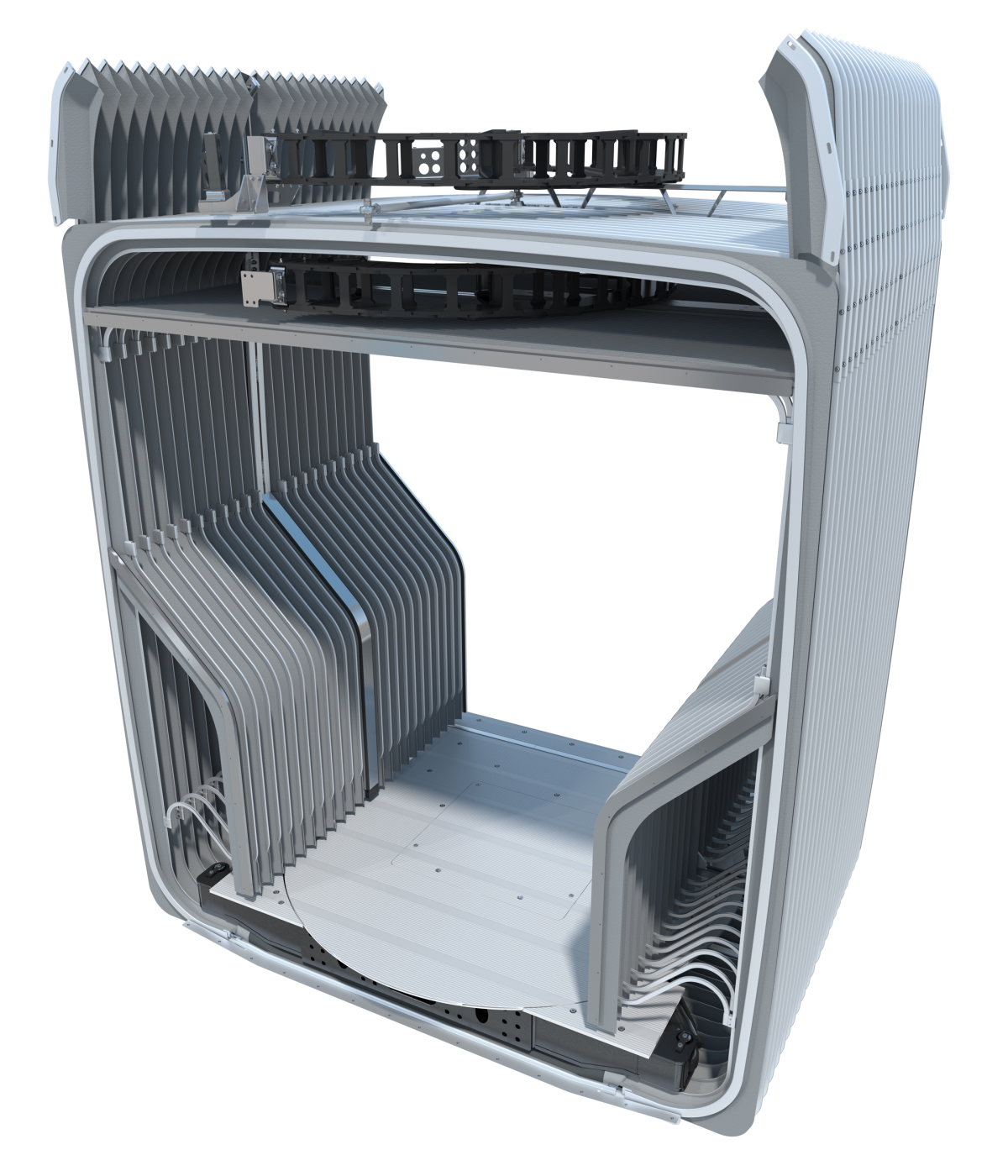

JOST BusLink articulated pusher bus system

The eponymous articulation is the most complex part of an articulated bus. The two vehicle elements are connected via an articulated swivel joint and an elastomer-coated bellow. The entire energy management as well as the wire harness to the hydraulic damper cylinders and the control sensors are located in the bellows.

The entire material construction is exposed to enormous stress. Comprehensive engineering expertise is required in the development of a system for articulated buses.

JOST, decades of experience in the commercial vehicle industry

As a world-leading producer and supplier of safety-critical systems for the commercial vehicle industry, JOST is now transferring its know-how to the bus industry. The innovative JOST articulation pusher bus system BusLink optimises the driving stability of an articulated bus with rear-wheel drive and ensures particularly smooth movement.

By transferring the thrust force to the front of the vehicle in a controlled manner, BusLink prevents the rear of the vehicle from lurching or breaking away.

The articulated turntable controller (ATC) is a core element of the system. It controls two hydraulic proportional damper cylinders and prevents the vehicle from buckling and swerving uncontrollably under any imaginable road conditions.

ATC: individual parameterisation of the input and output variables

The special feature of the JOST articulated turntable controller is the individual parameterisation of the input and output variables according to the requirements of the bus manufacturer.

The controller records the vehicle sensor data and forwards the output parameters to the hydraulic proportional damper cylinder. This prevents uncontrolled articulation or jack-knifing of the vehicle. The articulated turntable controller also enhances safety during unconventional manoeuvres.

The articulated front bearings, which cushion the pitching and rolling movements of the bus chassis, can also be individually adapted to the requirements of the driving dynamics. As a system supplier, JOST BusLink offers a customised product for every customer requirement for electric and hydrogen buses as well as for classically powered articulated buses.

In developing the articulated swivel joint, JOST drew on decades of experience in welded constructions in the commercial vehicle industry. The weight-optimised welded design of the articulation system significantly increases the payload of the bus. It also enables individual adaptation to every customer requirement.

On JOST ball bearing turntable and bellows

The articulation also includes the tried-and-tested JOST ball bearing turntable, with which the JOST success story began in 1952. The bellows is also a reliable and customised product. The design of BusLink ensures easy installation as well as maximum ease of maintenance and service. The associated repair solution is typically JOST with minimum effort, resulting in maximum customer benefit. Passengers also benefit as end users from more comfort and an increased sense of safety thanks to the “gap free” solution of the inner bellows.

The controlled transmission of the thrust force of the rear vehicle to the front vehicle is also a question of energy management. According to the customer’s specifications, the energy guiding system with the cable equipment runs at the top, at the sides or centrally through the articulation. A special high-voltage cable solution makes the system run seamlessly for electric bus applications.

“With BusLink, we are entering new industry territory. In Brazil, the system has already been in use in Mercedes-Benz do Brasil buses since 2022,” said Roland Ramirez, Director Program Management Global BusLink at JOST. “We are pleased to be able to demonstrate our comprehensive expertise in commercial vehicles for buses as well. It was a logical step to take. The innovative features of our transport and agriculture solutions, such as weight savings, flexibility, service-friendliness and high-tech materials, can be excellently transferred to bus systems.”