MAN kicks off a 2nd life project for use of vehicles’ batteries in stationary storage systems

MAN begins looking at the post-usage strategy for its batteries. The aim is to extend the life of the batteries in the first step and, if this is no longer possible, to recycle the raw materials contained in them. A second-life project for testing used MAN vehicle batteries in stationary storage systems has been started. […]

MAN begins looking at the post-usage strategy for its batteries. The aim is to extend the life of the batteries in the first step and, if this is no longer possible, to recycle the raw materials contained in them.

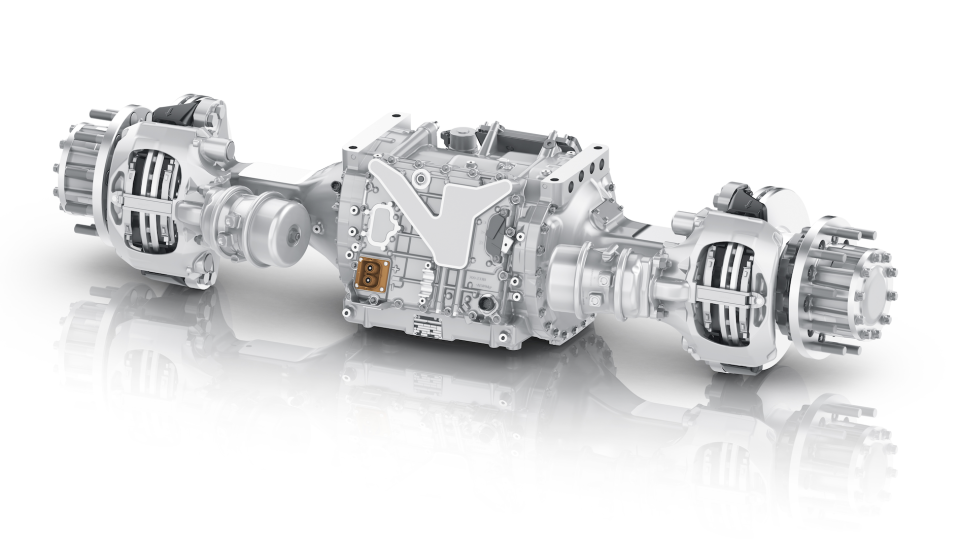

A second-life project for testing used MAN vehicle batteries in stationary storage systems has been started. MAN is indeed currently working with various partners and the University of Kassel on real projects to evaluate whether used truck batteries are suitable for stationary storage systems. For this purpose, around 120 truck battery packs with an energy content of 18.6 kWh per pack are being handed over to a storage system manufacturer. The battery packs originate from the first field trial with battery-electric distribution trucks from MAN, which began in Austria in 2018 and lasted three years. The project partner at the time was the Council for Sustainable Logistics (CNL).

It is planned to define a possible pilot project for a second life storage system based on MAN batteries from the first fully electric Lion’s City E series city bus.

MAN and second life batteries

In the truck sector, MAN Truck & Bus currently expects that electric trucks will have a share of 60% in distribution applications and 40% in long-haul transport in 2030. Electrification of city buses began earlier, with MAN expecting 50% of sales to be electric drives by 2025. These forecasts show that the commercial vehicle industry is only at the beginning of electrification, MAN says. The number of batteries that have come to the end of their service life in vehicles will therefore only reach industrial levels in around 10 to 15 years.

However, MAN announces “it is already working on developing a strategy for how the valuable batteries can be used in a resource-conserving manner in secondary applications. The analysis starts with the first life of the battery in the vehicle: the focus here is on training customers to drive, charge and use the vehicles so that the load on the battery is minimised. This can significantly increase the service life of the battery. If parts of the battery pack suffer a defect during use, e.g. individual modules no longer function, repair of the battery is planned as a first measure. The battery can then be used again in the vehicle”.

The batteries that come back to MAN after use in the vehicle are analysed intensively. In the event that the battery packs can no longer be used as so-called traction batteries, they are forwarded to secondary applications. Currently, there are three options for this: a second use in the vehicle after factory repair (second use), a second battery life (second life), for example as buffer storage of solar or wind power installations, and finally, the recovery of battery raw materials for new batteries in the sense of recycling.

MAN, a project for the second life of batteries

In the current project, the focus is on energy storage systems for industrial companies (e.g. peak shaving, means balancing charging peaks). The technical and business requirements for second life storage systems will be evaluated here. In particular, the aim is to obtain findings in the areas of safety, battery performance and remaining battery charging cycles. In addition, it is planned to define a possible pilot project for a second life storage system based on MAN batteries from the first fully electric Lion’s City E series city bus.

Recycling comes into play after the 2nd life of the batteries or in the event that batteries are no longer suitable for storage applications after vehicle use or an accident. MAN’s stated aim is to achieve a closed cycle for battery raw materials – from cradle to cradle. The goal is to use the raw materials recovered by the recycling partners, such as nickel, manganese, cobalt or lithium, in the new production of batteries. At present, the recycling rate is more than 70% in relation to the weight of the battery.

For recycling, MAN prefers a mechanical process followed by hydrometallurgical treatment. The valuable raw materials are recovered from the battery through a mechanical and hydrometallurgical process. MAN is part of the Volkswagen Group recycling network with recycling partners throughout the whole of Europe.