Pepper launches own development of Next-Generation High-Performance Battery

Pepper motion GmbH is now taking a decisive step towards the sustained further development of high-performance technologies and products: The start of in-house battery development is intended to bundle expertise and experience in the costliest component of an electric drive system with the highest development potential and to incorporate the practical experience gained in recent […]

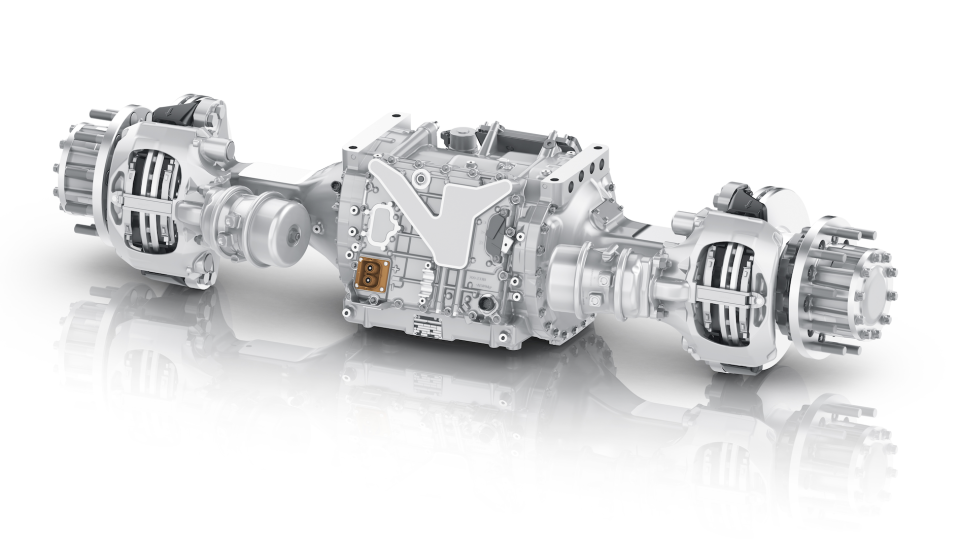

Pepper motion GmbH is now taking a decisive step towards the sustained further development of high-performance technologies and products: The start of in-house battery development is intended to bundle expertise and experience in the costliest component of an electric drive system with the highest development potential and to incorporate the practical experience gained in recent years in the commercial vehicle sector. A team of nine experts has been working since October 2021 in the recently opened pepper offices and laboratories at the Paderborn site. With this, pepper is accelerating the development of a next-generation battery system that has already been initiated.

The strategic lead of battery development is the responsibility of pepper CTO Dr. Matthias Kerler, whose research focus at the Chair of Automotive Engineering at the Technical University of Munich was in the field of battery system technology and electric powertrains. Michael Schön heads pepper’s internal Development Battery Systems department in Paderborn.

An interdisciplinary team of experts has formed a unique constellation to cover the many facets of the development of efficient and safe battery systems with high power density: development and testing of cells and systems, hardware development and design engineering of complete scalable modular battery systems, development of software for monitoring, and control of battery systems, and last but not least functional safety in accordance with ISO 26262.

The battery specialist team is already using its expertise to support departments of other commercial vehicle manufacturers in the development and integration of battery systems. The special demands placed on battery systems in the commercial vehicle sector are significantly higher than for passenger car models due to tough everyday operating conditions. Robustness, durability, safety, availability, energy efficiency, and sustainability are the key requirements of fleet operators for emission-free electric drive systems and the battery systems used in them.

The new strategic expansion will perfectly address these demanding requirements at pepper. The cooperation between the development teams in Denkendorf, Paderborn, and Vienna will ensure the best possible synergies and highly efficient, digital product development across multiple locations.

Hence, the expectations of pioneering technology leader pepper to outperform in international competition are high: «Our broad range of knowledge and experience in the field is unique in this combination within the market. It gives us the decisive edge in developing next-generation battery systems in the commercial vehicle sector. We will be incorporating all the latest trends in battery cell development into our future product development, provided they meet our high standards of functional safety and reliability», says Matthias Kerler, CTO pepper motion GmbH.