DC charging added (and roof-charging for the double-decker). New options for BYD ADL portfolio

BYD UK and Alexander Dennis Limited are adding operational flexibility to the Enviro EV range, which is now assembled entirely in the UK (chassis included). Additional charging options will be provided: in addition to AC plug charging, all of the partnership’s zero emission buses can now be specified with DC sockets, while double deckers also […]

BYD UK and Alexander Dennis Limited are adding operational flexibility to the Enviro EV range, which is now assembled entirely in the UK (chassis included). Additional charging options will be provided: in addition to AC plug charging, all of the partnership’s zero emission buses can now be specified with DC sockets, while double deckers also have the option of roof-mounted connector rails for OppCharge pantographs.

The first BYD ADL electric buses with DC sockets and roof-mounted charging rails will be delivered to operators in the United Kingdom this spring and summer.

ADL BYD e-buses: pantograph on the double-decker

As standard, the BYD ADL Enviro200EV single deck and BYD ADL Enviro400EV double deck buses are fitted with dual AC sockets, allowing them to be charged with one 40kW plug, or with two plugs for a combined charging power of 80kW. With compact infrastructure, AC charging continues to be a highly cost-effective solution for a majority of use cases in bus depots, the producers highlight.

DC charging via plug available for BYD ADL electric buses

DC plug charging offers higher charging power through a single connection and is now available as an option on all of the BYD ADL partnership’s single and double deck electric buses. Batteries can be charged at up to 102kW on the BYD ADL Enviro200EV, and up to 112kW on the BYD ADL Enviro400EV.

All BYD ADL electric buses can be specified optionally with the provision for both AC and DC charging on the same vehicle. Additionally, to provide parking flexibility while charging, the system offers options for charging socket location with customers able specify various installations of AC and/or DC sockets on the nearside or offside, subject to vehicle type.

OppCharge pantograph for the BYD ADL Enviro400EV

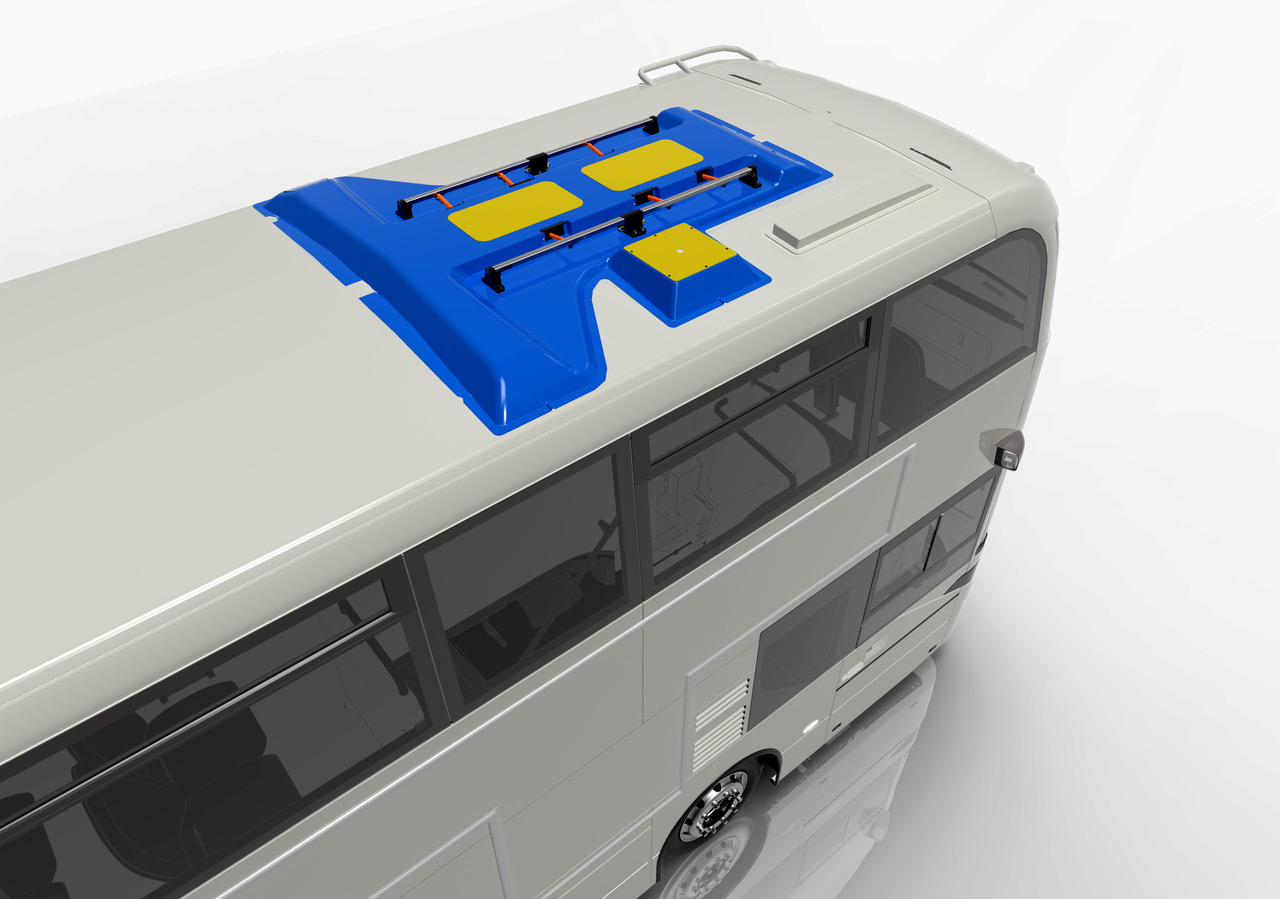

What is more, the BYD ADL Enviro400EV double decker can now be specified with roof-mounted rails to connect with pantographs built to the international OppCharge standard, which are lowered from their gantry to the vehicle’s roof.

BYD’s Battery Thermal Management System (BTMS) is also installed with the capacity to deliver a peak charging power of 300kW for rapid recharge of batteries, although it may also be used at lower power in bus depots where infrastructure constraints prevent the installation of plug chargers next to the vehicles’ parking positions. BTMS is a liquid-cooled, emissions-free technology designed to maintain an optimum battery temperature and, therefore, maximum efficiency for the vehicle.

Paul Davies, ADL President & Managing Director, said: “As a business we pride ourselves on innovation and customer focus and we understand that bus operators require operational flexibility to facilitate the transition to zero emission buses. That is why we are adding DC charging and pantograph solutions for our electric buses, which are built in Britain to benefit our economy and develop the country’s expertise in clean vehicle technology.”

Frank Thorpe, Managing Director at BYD UK, said, “This development underlines BYD’s world-renowned expertise in battery technology and energy management, in addition to its BEV manufacturing capability. Working in partnership with Public Transport Operators has allowed us to develop solutions that benefit customers out on the road and also back at the depot. These close relationships,” he said, “are helping bring clean, sustainable public transport to more and more people in towns and cities across the UK.”