Solaris Urbino 12 Electric: the ID card of the European most successful electric bus model

Solaris Urbino 12 Electric is a quite well-known model for those into the European bus market. with over 2,500 e-buses delivered, Solaris is today the leading European player in the zero-emission bus sector. The New Solaris Urbino, a highly successful model launched in 2016, have been available in a BEV version right from the start […]

Solaris Urbino 12 Electric is a quite well-known model for those into the European bus market. with over 2,500 e-buses delivered, Solaris is today the leading European player in the zero-emission bus sector.

The New Solaris Urbino, a highly successful model launched in 2016, have been available in a BEV version right from the start (while the previous-generation electric Urbino had already been presented in 2011), allowing the dynamic Polish manufacturer to gain great experience in this type of alternative drive. And new features have been launched in early 2024. Let’s see in details…

This article was previously published on the February 2024 issue of Sustainable Bus magazine

Solaris Urbino 12 Electric: plenty of choice for driveline

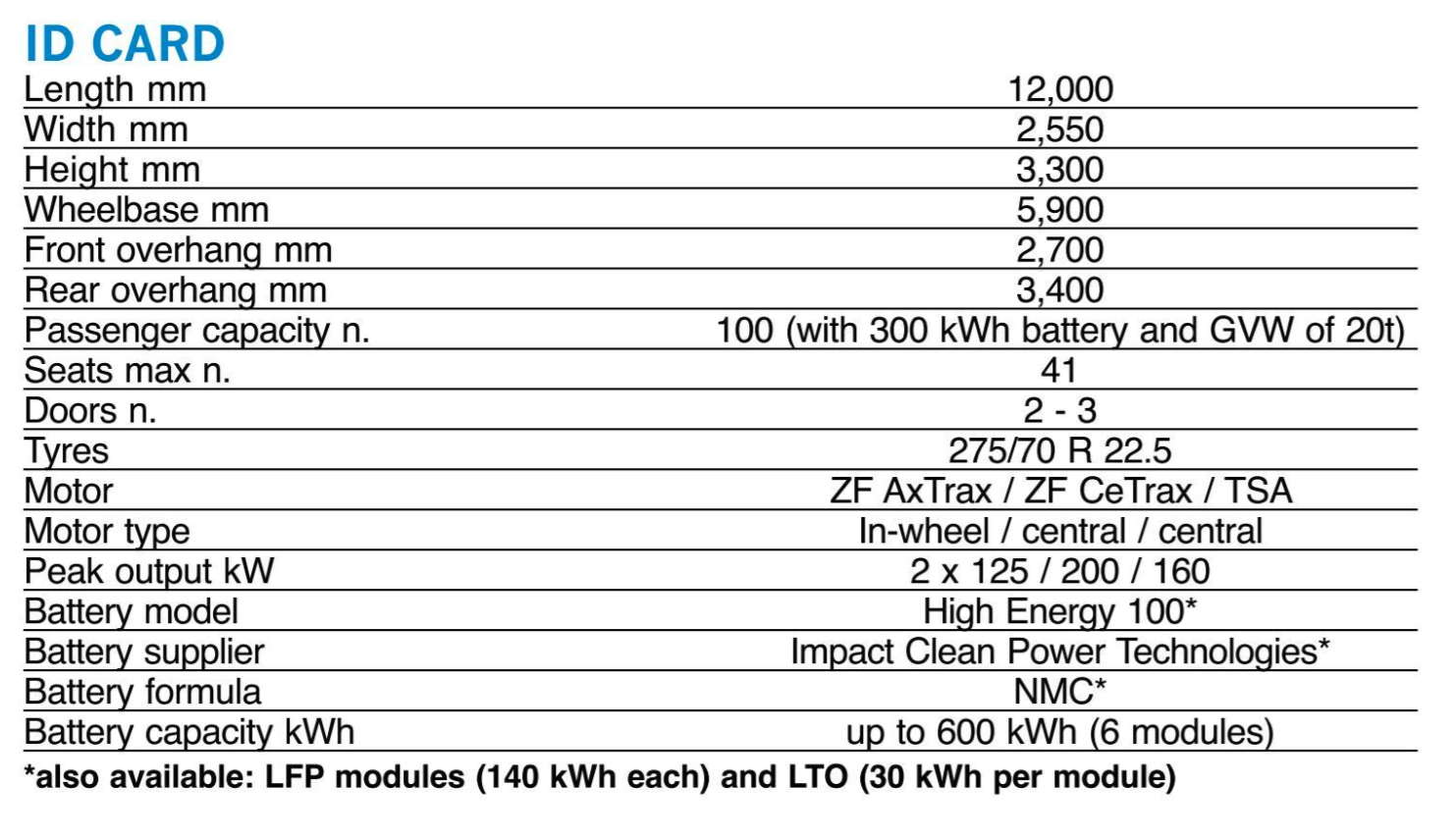

As an alternative to the ZF AxTrax e-powered axle, a central motor from Austria’s TSA (model TMF35-28-4) or ZF’s CeTrax Cx220 110B have been available for a few years now on the Solaris Urbino 12 Electric, so that supporters of one or the other solution can be satisfied.

The increasingly strong collaboration with Impact Clean Power Technology has led to the development of new High Energy 100 batteries, with NMC chemistry and a capacity of 102.9 kWh per module. This modules have the same size of the previously fitted range, capable of 88 kWh. The weight is also similar (just about ten kilos more), for a 14 percent benefit in terms of energy capacity. The new batteries also make it possible to upgrade vehicles born with the 88 kWh Impact modules or even the first-generation 40 kWh modules, in this case more than doubling the range.

The performance of the three variants ranges from 160 kW of power for the TSA, to 220 of the CeTrax and up to 2×125 kW of the ZF’s “motor wheels” (with as much as 22,000 Nm of total maximum torque downstream of the integrated hub reduction). If one of the central motors is chosen, one can logically intervene on the transmission ratio, opting for a greater or lesser reduction depending on the mission profile required.

The position of the central motor is, curiously enough, in front of the rear deck, on the left-hand side; a solution that requires a forward extension of the base close to the wheels and the positioning of a rearward-facing two-seater behind the disabled seat.

As for the drive, both solutions have their pros and cons. Among the advantages of the motorised axle is certainly the smaller internal size. In favour of the mid-axle motor, on the other hand, there is quieter operation and decidedly easier maintenance, as well as (it seems) greater efficiency in energy recovery during braking.

In any case, letting the customer choose the preferred driveline already puts Solaris in an advantageous position compared to competitors who go their own way, sometimes without being sure of which solution is actually the best.

New generation Solaris Urbino 12 Electric

Let’s talk about the updates introduced to the Solaris Urbino 12 Electric at VDV-backed Mobility Move exhibition, held in Berlin at the beginning of March.

The increasingly strong collaboration with Impact Clean Power Technology, a Warsaw-based company specialising in batteries and charging systems (with plans to establish a gigafactory), has led to the development of new High Energy 100 batteries, with NMC chemistry and a capacity of 102.9 kWh per module. This modules have the same size of the previously fitted range, capable of 88 kWh. The weight is also similar (just about ten kilos more), for a 14 percent benefit in terms of energy capacity. The new batteries also make it possible to upgrade vehicles born with the 88 kWh Impact modules or even the first-generation 40 kWh modules, in this case more than doubling the range.

“The rear structure of the vehicle changes completely”

In addition, the Berlin fair was also an opportunity to make official the new arrangement of the drive components, as already anticipated at Busworld in Brussels on the 18-metre. Basically, the rear structure of the vehicle changes completely. The engine tower inherited from thermal vehicles, which housed part of the batteries, the inverter and the cooling units are gone. The batteries are therefore all transferred to the roof. They are distributed between the front and rear areas, similarly to what other manufacturers have already done.

This layout, which is decidedly more orderly, allows up to six 100 kWh modules to be accommodated on the 12-metre and up to eight on the 18-metre. This enables the Urbino to achieve respectable capacities (and therefore range), even taking into account a DoD (= depth of discharge, i.e. the energy that can actually be used) of 80 percent.

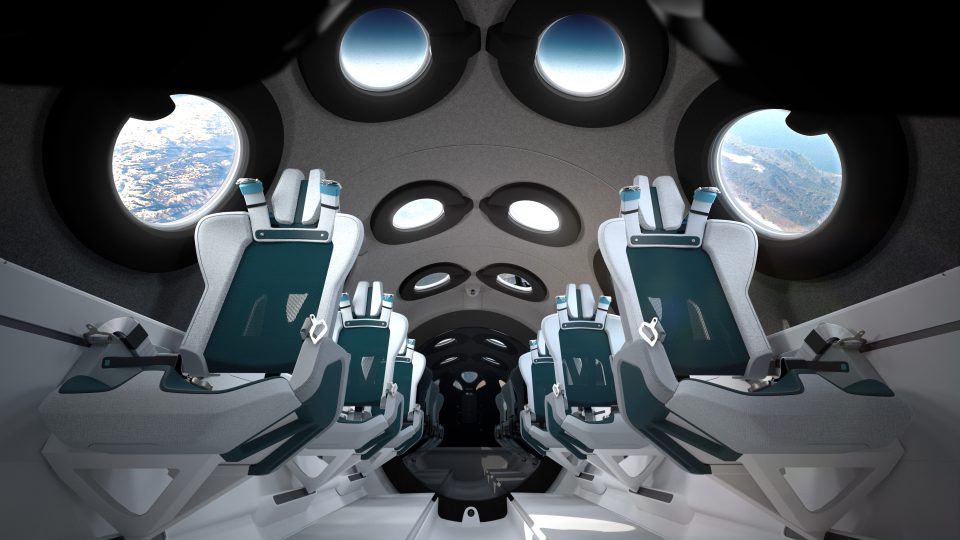

The greatest benefits of the new layout can be seen inside, where four to seven more passenger seats can be found in the area previously occupied by part of the batteries. The entire passenger compartment is also surrounded by windows, with no more cabinets or closing panels.

As an alternative to the ZF AxTrax e-powered axle, a central motor from Austria’s TSA (model TMF35-28-4) or ZF’s CeTrax Cx220 110B have been available for a few years now on the Solaris Urbino 12 Electric, so that supporters of one or the other solution can be satisfied.

All kind of batteries available on Solaris Urbino 12 Electric

However, all other types of batteries remain on the list: 140 kWh LFP batteries (the cheapest) for plug-in recharging, and 30 kWh LTO batteries for flash and opportunity recharging by direct or reverse pantograph. On this point too, there is maximum flexibility.

The standard position of the CCS2 socket is near the right front wheel, to which a second specular recharging point can be coupled to the left, front centre or rear right. With the exception of a few minor optimisations on components and production costs, the Urbino otherwise retains all the characteristics that have taken it to the third place of the European market for city buses. The self-supporting reticular structure is still made of stainless steel profiles and tubulars welded together, onto which the reinforced fibreglass headers, roof cladding sheet and windows are glued. The modular side panels, on the other hand, are interlocking and screwed, and they are easy and quick to replace. The aluminium doors, all fitted with specific hinges that allow almost total rotation, contain the overall size in the open position.

Let’s get on board

The driver’s seat is of a fairly traditional design, with an adjustable dashboard integral with the steering wheel and compliant with VDV standards. It is supplemented by a practical dashboard to the left of the driver and room for additional controls and control units above the driver’s head. The ISRI or Grammer brand seat is pneumatic with lumbar adjustment, which can be combined with cushion heating and backrest ventilation functions.

The passenger compartment is very spacious, also thanks to the new battery arrangement, and only partially affected by the presence of the motor, if any. The windows can all be fitted with a vasistas or sliding opening, with a choice of two levels of transparency, single or double-glazed. Evening lighting is provided by two rows of LED lamps arranged longitudinally and pointing downwards at approximately 45 degrees, with transparent plastic covers featuring a rather classic appearance. Handrails are in painted steel or stainless steel, with an intelligent modular assembly system.

The basic seats are the Kiel Ideo or Ster 8MU, made of plastic with or without velour covers; alternatively, the Ruspa Citipro. Yet another example of Solaris flexibility.