Safra will unveil the HYCITY fuel cell bus at Busworld. Our interview with CCO Eric Baleviez

Safra made a remarkable appearance at the Paris 2022 Euro Mobility Expo, where they officially announced the launch of their hydrogen-powered HYCITY bus (ten units are going to be delivered in Dunkirk). This innovative vehicle is set to replace their Businova model. In the meanwhile, at UITP Summit 2023 Safra showed a Intouro retrofitted with […]

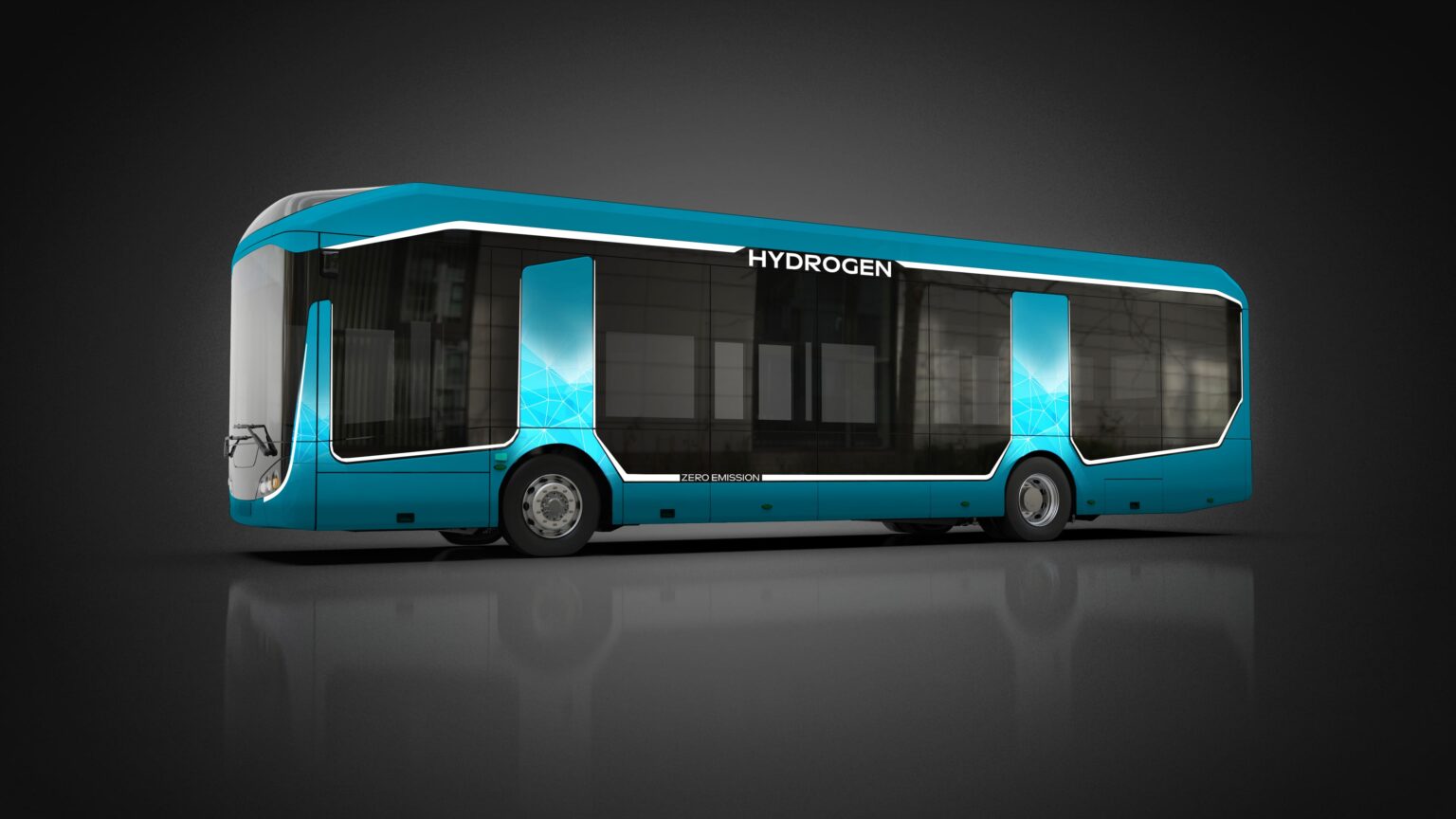

Safra made a remarkable appearance at the Paris 2022 Euro Mobility Expo, where they officially announced the launch of their hydrogen-powered HYCITY bus (ten units are going to be delivered in Dunkirk). This innovative vehicle is set to replace their Businova model. In the meanwhile, at UITP Summit 2023 Safra showed a Intouro retrofitted with an in-house developed fuel cell kit.

In this interview with Safra Chief Commercial Officer Eric Baleviez, who joined the French company in early 2022, we provide updates on the progress of HYCITY and share details about its upcoming public presentations at the Busworld trade show in Brussels and the RNTP trade show in Clermont-Ferrand. Additionally, we delve into the features of HYCITY and Safra’s commitment to zero-emission vehicles.

Safra, the HYCITY to be showed at Busworld

Safra was among the headliners at the Paris 2022 Euro Mobility Expo, announcing the launch of the hydrogen-powered HYCITY, which would replace the Businova. Here, where are we standing with this product? Is there any news?

We will display the HYCITY at the next Busworld trade show, in Brussels from October 6 to 12th. It is a great opportunity to do the first public presentation of our new generation hydrogen bus. Following on from this, the HYCITY will also on our stand at the French trade show RNTP, which this year takes place in Clermont-Ferrand from October 17 to 19th.

Since the announcement of this new product at the Paris 2022 Euro Mobility Expo our engineering teams worked hard to design our new hydrogen vehicle taking into account customers and market expectations in terms of performances, maintainability, road behaviour, customization capabilities. It takes time to do this properly, in a pragmatic step by step approach. We are now ready to deliver and with already a very nice order book.

In 2024, which will see less exhibitions, we intend to run a roadshow throughout France with the HYCITY, to interested cities for an onsite demonstration. This will allow our customers to directly test the vehicle on their lines, and to exchange about specific demands they may have.

The HYCITY has been presented as a 100 percent H2 bus that was created for Class I, but aims to ‘conquer’ Class II as well: in the portfolio it is available in a 12-meter 3-door version with a completely flat floor. Correct? Any other features you would be willing to share?

Thanks to 10 years’ experience with the Businova, we have gained a real-life experience of the electric powertrain and hydrogen energy. The HYCITY has been designed as a full hydrogen vehicle with an aim to facilitate operation and improve the vehicle’s TCO. It is also a more conventional vehicle with a standard size and shape (12 m long and integral flat floor) and with either 2 or 3 doors, this latter configuration becoming a must in the market which we couldn’t offer with the specific layout of Businova.

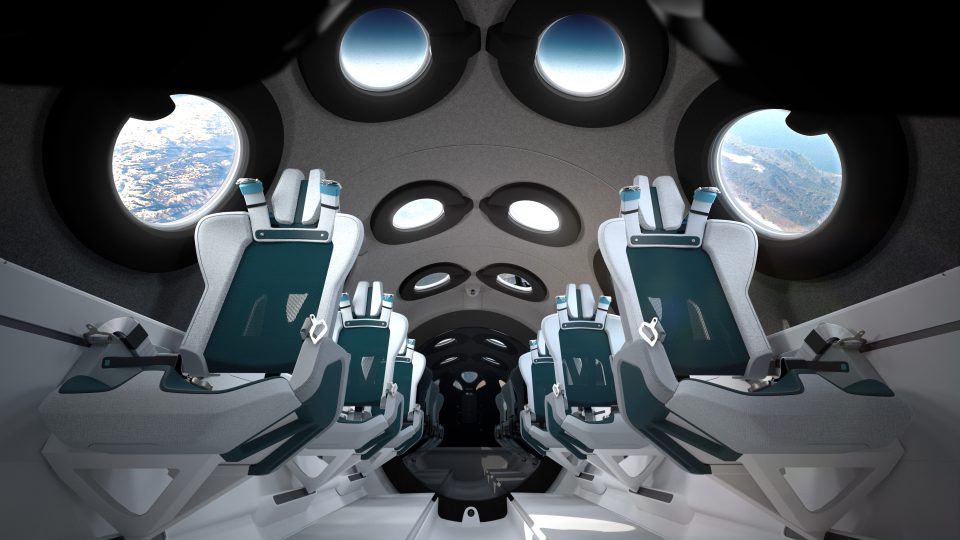

Enhanced passenger experience has been included in our design specifications and HYCITY features a bright and accessible passenger aerea. Operability, maintainability, ergonomical driver’s cab, integration of ADAS and on-board systems have also been taken care off in this new generation. Class 2 configuration is in our product roadmap and will target other European markets.

What about the 18-meter version planned? When will it be available?

The 18m HYCITY development has been launched, and we plan to present this new model in 2025, after testing phase planned late 2024. Meanwhile, our engineering team works on retrofitting existing ICE to ZE vehicles. This is the other major topic of Carbon-free Mobility and PTOs are more and more interested by this solution.

Safra strategies focus on hydrogen

As a company, you have announced a farewell to the hybrid technology, focusing all on zero emissions: can you explain the reasons for this choice and the results you are achieving / aim to achieve? Any figures concerning actual production volumes and targeted capacity?

First of all, we have chosen zero emission vehicles, putting aside all other options, because we are convinced that there is simply no other choice as we face always growing air pollution and carbon emissions.

We launched the Businova program in 2011, with the aim ultimately of designing a zero-emission vehicle, with a focus on hydrogen, a technology we’d been following closely for several years. At the time, this technology was not yet mature enough to be marketed and it was just the first roll out of electric buses. So, we designed the first rechargeable electric version of the Businova, based on an architecture that would enable us to adapt the motorization to new energies in the future, and hydrogen was one of them. As a result, we were able to rapidly convert Businova to hydrogen, whereas other manufacturers had to go through a full redesign of their platforms to offer hydrogen versions. In 2018 we pioneered with the first hydrogen bus in France.

Thanks to this early start we learned a lot on safety, software management, hydrogen consumption, vibrations and noises optimization, performance modelling. Our customers now benefit from our gained experience and knowledge, and we are very confident to achieve the performance we announce with HYCITY.

This also explains why we are well positioned in the hydrogen retrofit market, because we are both fully knowledgeable with the technical constraints caused by hydrogen , and familiar with increasing vehicles’ life thanks to our long-standing refurbishment expertise.

Moreover, Safra aims to export on markets outside France: which countries have you put in your sights?

We will first target continental Europe as launching a right-hand vehicle would deeply impact the chassis and homologation.

We are currently working on improving our after sales structure in France, because as you know, availability of vehicles, is directly linked to spare parts availability, ability to contract full maintenance, preventive maintenance, and this require a high level of organization and reactivity.

Then we will start to expand our maintenance network outside France.

Today our commercial team monitors the European market in order to understand its technical and performance requirements. More specifically, we pay a closer attention to the evolution of hydrogen mobility in Germany, Italy, Spain, Benelux, Scandinavia and we have already started planting seeds with potential partners to set up local customer service offers.

And retrofit is also part of the match

At the end of 2022 you announced a partnership with Plastic Omnium to support the development of the HYCITY hydrogen bus range and retrofit service for the conversion (from diesel to hydrogen) of coaches. Can you be more specific on this partnership?

Safra has entered a long-term industrial partnership with Plastic Omnium for 2 products of its range. For HYCITY, Plastic Omnium supplies us with the type IV high-pressure hydrogen vessels. For H2-PACK, our coach retrofit kit we will install on a first series of 15 coaches, Plastic Omnium supplies us with the fuel cell systems and with the hydrogen tanks. Plastic Omnium’s fuel cell can deliver 100 kW in peak power (71 kW average), which is mandatory to allow coach travels up to 100 km/h.

With the major investments made over the last 10 years, Plastic Omnium will also provide required high level technical assistance throughout Europe on these critical components. This partnership confirms the commitment of both companies to sustainable mobility and, more generally, a commitment to address environmental issues.

Among other things, Safra was awarded Europe’s largest bus retrofit contract to convert diesel buses to hydrogen. Repowering is indeed quite an interesting topic nowadays, but its potential role in the decarbonization process will depend on the financing that will be made available. May you outline where and how repowering of diesel buses into zero emission is financed as of today?

We all know that as of today hydrogen technology applied to mobility is more expensive than fossil fuels, but I think this is not anymore, the question. We need to change to more sustainable choices including for our public mobility, zero emission vehicles are the only viable option to improve air quality in our cities. EU and many European governments provide strong financial incentives to help this transition and to support complete hydrogen ecosystems, as in France with the ADEME’s AAPs.

Retrofit is today a viable option for vehicles registered for more than 5 years and which have still around 10 more years to run as it allows to cut their emissions while offering comparable performances and prevents to scrap vehicles which would be an ecological and economic absurdity. Our historical activity of extending vehicle life through midlife refurbishment has proved time and again that renovating and repairing these vehicles is a considerable cost-saver for Mobility Authorities.

Retrofitting also accelerates the decarbonization of mobility. The availability of new zero-emission vehicles is very limited or even non-existent for usages such as intercity coaches. By converting the existing fleet, we enable the local authorities to meet European regulations more rapidly and at a lower cost.

Today, an intercity coach retrofit costs around €300,000. With the massification of the hydrogen market, thanks to the increase in demand, which is already being experienced, availability and price of hydrogen components will rapidly improve.

At UITP Summit your stand focused on the topic of retrofit…

Yes, we started the 2023 transport fairs season at the UITP in Barcelona exhibiting our hydrogen retrofit kit. We had on our stand a Mercedes Intouro bus from the Region Occitanie fitted with the H2-PACK kit to transform this diesel vehicle into hydrogen. We are currently working on the retrofit of 15 similar vehicles for this customer.

We made this choice because there is a strong demand for heavy vehicle retrofits and very few offers. This is a great opportunity to showcase our technical know-how in this type of conversion to the international community and at the same time to demonstrate our commitment to the energy transition.

Our focus or Busworld Brussels, will be the first public display of HYCITY. Where could there be a better place for this kind of event!

We are eager to show this vehicle to the public, and to find out how this new generation of hydrogen buses will be received at the event.