Market, infrastructure, product roadmap, the role of fundings: Daimler Buses’ CEO Till Oberwörder speaking

Further expanding market leadership, becoming even more competitive, gaining a position of strength. These are the goals of Daimler Buses, well mapped out in the brand's roadmap to zero emissions in all mission profiles. Our interview with Till Oberwörder, CEO of Daimler Buses

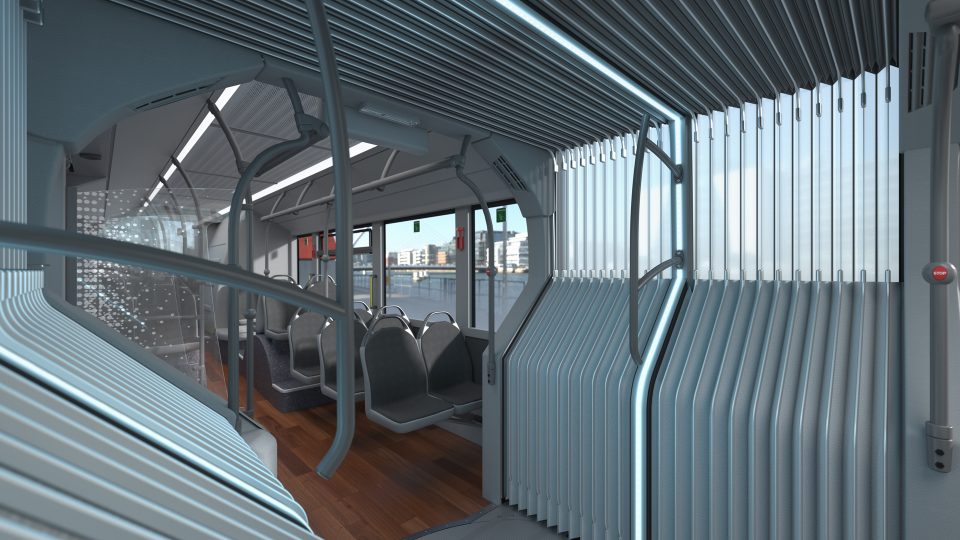

The ideas are clear and have enabled the group to respond well to the hard knocks of the Covid annus horribilis and also to the medium- to long-term effects. Daimler Buses started series production of battery-powered city buses in 2018 (with the Mercedes eCitaro range), developed a 12- and 18-metre fuel cell model, and now, in the near future, it will be the turn to bring electric to Class II as well, while by the end of the decade – what the company has labelled ‘the bus decade’ – the first battery-powered or hydrogen-powered coaches will also arrive.

Not only products, but also services: in summer 2023 Daimler Buses Solutions, specialising in the design and construction of electric infrastructure, saw the light of day. In Hannover, we took stock with Till Oberwörder, CEO of Daimler Buses.

We have a formula: product times infrastructure times TCO. If one of these parameters is zero, the multiplication result is zero. The products are on the market, TCO can be achieved, but infrastructure is not yet developing at a higher speed.

Till Oberwörder, CEO of Daimler Buses

Till Oberwörder, focus on the markets for electric buses

What are the key markets for buses in the next 5-10 years globally, and how do you plan to seize opportunities in these regions?

We are focusing on our classic core markets Europe, Latin America and Mexico. There we are the undisputed market leader. We believe, depending on market expectations, that we can offer the right products, be it a combustion engine vehicle or a ZE vehicle. We are actively pushing projects to support customers in the transition from diesel to electric, offering complete solutions, including the conversion of depots, through our subsidiary Daimler Buses Solutions. We are currently transforming over 20 depots of various sizes throughout Europe. Moreover, another important region for us are the United States. There we offer a coach specially developed for North American requirements, the Mercedes-Benz Tourrider.

And what about coaches?

We definitely see the market coming back after Covid. In general, we can say people want to travel again and people want to travel with sustainable products. And even today a diesel coach is a sustainable product when it comes to the CO2 emissions per passenger.

Which market is the most promising and sensitive for electric buses?

Europe is definitely the driving force market for battery-electric buses, thanks to fleet renewals and growing demand for sustainable solutions. We are putting ourselves into the position of our customers trying to fully understand their business model to support them in the best possible way. This was the reason for founding Daimler Buses Solutions, for instance.

A changing landscape for bus manufacturing in Europe?

According to the latest financial results for the first half of 2024, Daimler Buses achieved a 313% leap in adjusted EBIT compared to Jan-Jun 2023. Which was the reason for that?

The overproportional growth is partly due to the fact that 2023 was still affected by the pandemic. The market in 2023 was still suffering. During Covid, Daimler Buses continued to invest in new products and we improved our process efficiency, despite budget restraints. We went through our processes and fine-tuned them, also finding an agreement with the work councils in order to use our production network more flexibly. All these measures have given us a head-start now that the market is back and made us much more resilient as a company.

Many OEMs in Europe are suffering big financial pressure, some large groups have decided to change their business model and focus only on chassis production. Are we witnessing a paradigm shift in the bus and coach industry in Europe?

I’m not sure if there is a universal paradigm shift, but we believe that our business model, which includes integral buses in Europe and chassis-body concepts in Latin America, is a good set-up.

Infrastructure and fundings for zero emission buses

However, looking at the market, profitability in zero emission technologies, even with rising demand, looks like quite difficult to achieve…

We have a formula: product times infrastructure times TCO. If one of these parameters is zero, the multiplication result is zero. The products are on the market, TCO can be achieved, but infrastructure is not yet developing at a higher speed. We are all (OEMs and customers) continuously discussing how infrastructure can be ramped up faster. In urban traffic it’s easily possible. But if we look at long-distance operations, there are places where coaches have to go that are far from highways. It’s a crucial point.

The transition to electric buses had clearly begun in cities, for logical reasons. The next phase involves expanding e-bus products to interurban areas. By the end of the decade, battery-electric buses and coaches for long distances are expected to be introduced. The main challenge, again, is to build the charging infrastructure network. Technically, what we have to achieve in Europe is 400 charging stations built per month with a capacity of 400 kW.

Till Oberwörder, CEO of Daimler Buses

Your division is keeping a large share of manufacturing activities in Europe. Which are the plans for the Turkish plant?

Turkey is a key pillar in our European production network for buses, a fully integrated production hub in our network of five production sites in Europe: two in Germany, one in France, one in Czech Republic.

Funding for electric city buses is being stopped in some important markets, such as Germany. Do you see this having an impact on the development of e-mobility in public transport? Which role should we expect for subsidies in the future?

The broad use of buses with zero-emission drives essentially depends on transport companies investing in the vehicles and infrastructure – and being able to operate them profitably. The funding was consequently an important financial support in the transformation to emission-free passenger transportation. By discontinuing the funding, we are depriving our customers a helpful incentive to invest in vehicles with emission-free drives as quickly as possible and also to establish an adequate charging infrastructure in order to achieve the ambitious CO2 reduction targets in Germany and Europe at a time when diesel buses are still significantly cheaper to purchase.

The roadmap for zero emission bus production at Daimler Buses

Daimler Buses has committed to marketing intercity e buses as of the middle of the decade and electrified coaches by 2030. Can you elaborate on the roadmap, the challenges and opportunities this presents, especially in terms of investments?

We communicated our roadmap a couple years ago. The transition to electric buses had clearly begun in cities, for logical reasons. The next phase involves expanding e-bus products to interurban areas. By the end of the decade, battery-electric buses and coaches for long distances are expected to be introduced. The main challenge, again, is to build the charging infrastructure network. Technically, what we have to achieve in Europe is 400 charging stations built per month with a capacity of 400 kW.

Bringing the production of critical components (to begin with, motors and batteries) in house is a goal that your group is pursuing?

Daimler Buses already produces some important components, such as seats, in-house. For other components, we leverage synergies with the truck division. Today we take engines and drivetrains from the same production lines and integrate them into the buses. We have the same logic in place for e-mobility, and now we will move step by step together.

Is investing in battery cells something that could make sense, in such a highly competitive and fast-evolving market?

An answer to this are partnerships, such as the one we have in place with Accelera by Cummins and Paccar for battery production called “Amplify Cell Technologies”.