Unleash the potential of your eBuses batteries, by PowerUp

The performance and safety evaluation of electric vehicle (EV) batteries is a multifaceted process that extends beyond reliance on a single key performance indicator. Instances of electric buses breakdowns or fires typically stem from a culmination of factors rather than a singular event.

Authored and sponsored by PowerUp.

It follows a first contribution on “Unleashing value with battery analytics in the mobility revolution“

The performance and safety evaluation of electric vehicle (EV) batteries is a multifaceted process that extends beyond reliance on a single key performance indicator. Instances of electric buses breakdowns or fires typically stem from a culmination of factors rather than a singular event.

These contributing events can gradually lead to performance degradation before eventually leading to battery failure or thermal runaway. Examples of potential performance degradation or fire risks encompass the limitations of battery management systems, and the emergence of temperature and voltage spreads as the battery undergoes ageing.

Make sure your buses are performing well from day one

Every electric bus lithium-ion battery is equipped with a Battery Management System (BMS) that actively monitors and regulates battery operations. The primary role of the BMS is to guarantee the secure functioning of the battery. It oversees critical parameters, such as maintaining each battery cell within safe voltage, current, and temperature limits during charging, discharging, and open circuit conditions. The BMS is designed to intervene and cut power in case of issues, preventing potential worst-case scenarios. On the other hand, while performing its safety functions, BMS can also provide State of Health (SOH) and State of Charge (SOC) indicators.

To achieve optimal performance, regular reassessment of these battery State of Health (SOH) and State of Charge (SOC) indicators is imperative. Accurate measurements not only unveil potential issues with Battery Management System (BMS) calibration but also establish a foundation for reliable fleet operations. Fleet operators can rely on these indicators to fine-tune their electric bus operations, enhancing efficiency and extending the overall lifespan of their valuable assets.

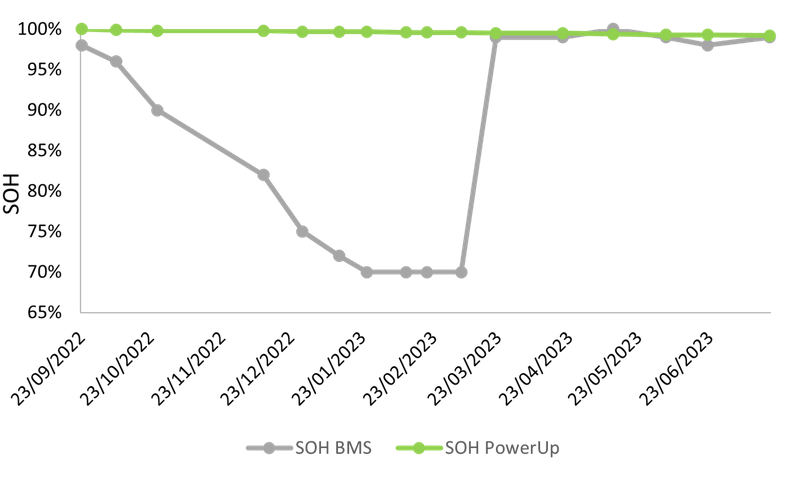

Unveiling potential issues with Battery Management System (BMS) calibration is of paramount importance in the seamless operation of electric bus fleets. During the commissioning phase, the precision and accuracy of the BMS are critical parameters to verify to ensure optimal battery performance and safety. Battery analytics play a crucial role in this context by actively monitoring and analyzing BMS data, allowing for the early detection of calibration discrepancies.

In the example provided (Figure 1), recently commissioned buses display irregular State of Health (SOH) degradation. Regrettably, it took the operator over six months to identify the issue and engage with the manufacturer, resulting in a period of blind operation during this timeframe.

Identifying these issues at an early stage enables bus operators to proactively engage with their asset providers and OEM, advocating for necessary software updates and fine-tuning to rectify calibration inaccuracies. This proactive approach not only enhances the reliability of the electric bus fleet but also fosters a culture of continuous improvement, ensuring that BMS calibration remains optimized throughout the operational lifespan of the vehicles.

Predict how your buses are going to age

As we delve into the nuances of maintaining peak performance, it becomes evident that the heartbeat of any electric bus fleet lies in the precision of its battery degradation monitoring. These indicators not only fine-tune systems but also set the stage for the seamless operation of these eco-friendly giants.

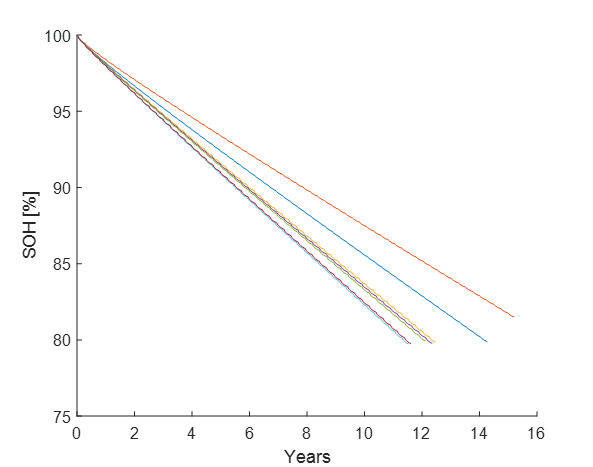

We now explore predictive tools, with a focus on Remaining Useful Lifetime (RUL). RUL acts as a predictive tool for fleet managers, enabling them to anticipate and prevent potential issues in battery health. Through simulating battery degradation based on specific usage profiles, fleet managers gain valuable insights. This foresight aids in strategic maintenance planning, reducing downtime and optimizing overall fleet performance.

In Figure 2, the comparison illustrates the aging patterns of 7 similar electric buses subjected to varying operational conditions. In this case, low temperatures tent to accelerate battery aging whereas in other cases, high temperatures highly impact battery degradation. Anyway, the discernible temperature variations prompt a need for analysis to differentiate between conditions imposed by regular operations and those stemming from potential issues in the battery system architecture.

Prevent battery safety issue

As we shift from meticulous battery health monitoring to predictive analytics, the focus turns from reactive to proactive fleet management. The integration of predictive tools transforms the approach, empowering fleet operators not just to address but to anticipate and mitigate issues before affecting operations.

The importance deepens as we delve into the critical role of early detection in averting safety concerns. In the intricate operations of electric buses, subtle cell imbalances and potential battery failures are concealed challenges. Here, battery analytics function as vigilant guardians, recognizing warning signs before they evolve into performance issues or safety incidents. The capacity to act on early indicators becomes a pivotal factor, enhancing both reliability and safety significantly.

Conclusion

In the complex landscape of electric bus operations, a cohesive approach integrates proactive monitoring, predictive planning, and early issue identification. Battery analytics stand out as instrumental contributors, addressing intricate challenges. The ongoing vigilance in monitoring battery health, the strategic use of predictive tools, and the timely identification of potential issues collectively reshape the operational landscape of electric bus fleets. As sustainability and safety become central in urban transportation, the influence of battery analytics becomes a driving factor, guiding electric buses toward a future where intelligence, foresight, and reliability meet operational challenges.

In the final article, we will focus on the second life management of electric buses batteries: how to overcome costs-benefits tradeoffs and monetize the batteries on the second life market?