Next generation e-bus range by Alexander Dennis: Enviro100EV and 400EV unveiled

Alexander Dennis has launched today, 1st November 2023, its next generation of battery-electric buses for the UK and Ireland (announced in August 2022) with the unveiling of the new Enviro100EV small bus and Enviro400EV double decker. They are part of a wider family of next-generation zero-emission buses. An international version of the Enviro100EV is under […]

Alexander Dennis has launched today, 1st November 2023, its next generation of battery-electric buses for the UK and Ireland (announced in August 2022) with the unveiling of the new Enviro100EV small bus and Enviro400EV double decker. They are part of a wider family of next-generation zero-emission buses.

An international version of the Enviro100EV is under development, as is the autonomous Enviro100AEV and an open-top variant of the double deck Enviro400EV.

The next generation of Alexander Dennis battery-electric buses for the UK and Ireland will be completed in 2025 with a new Enviro200EV single decker that will also be fully engineered and built in house.

The new buses have been engineered fully in house as zero-emission vehicles from the ground up. Alexander Dennis highlighted that “in addition to its next-generation buses, Alexander Dennis will continue to sell and support electric buses built in partnership with BYD“.

Alexander Dennis new Enviro100EV and 400EV are born

The 11.1m-length Enviro400EV double decker is designed to shift the crowds on busy urban and interurban routes, advancing electrification options for core services across the UK and Ireland with a range of up to 260 miles, ADL says. The Enviro100EV is just 8.5m long and 2.35m wide.

The new Enviro100EV and Enviro400EV come with a five-year warranty as standard. Production of customer orders for both vehicle types has now begun, with deliveries expected in the first months of 2024.

Alexander Dennis has integrated the new zero-emission driveline in house, working with leading technology partners such as Voith, that supplies the Voith Electrical Drive System (VEDS), which has been specifically developed for the requirements of urban and interurban buses. While the Enviro100EV uses the medium-duty variant of VEDS, the heavy-duty version is employed in the Enviro400EV for gradeability and maximum reliability even at higher operating speeds.

The Enviro 400EV features batteries in the chassis

The battery system has been developed in partnership with Impact Clean Power Technology. Using NMC lithium-ion cells, it delivers a higher total energy throughput – up to 1.4GWh in the Enviro400EV, while battery capacity is up to 472kWh on the Enviro400EV and up to 354kWh on the Enviro100EV.

The manufacturer states that “Sample analysis shows that thanks to its class-leading 1.4GWh energy throughput, the Enviro400EV will be able to cover two consecutive seven-year contract terms on typical Transport for London routes without a battery change, or typical provincial routes for up to 20 years with just one mid-life change of batteries”.

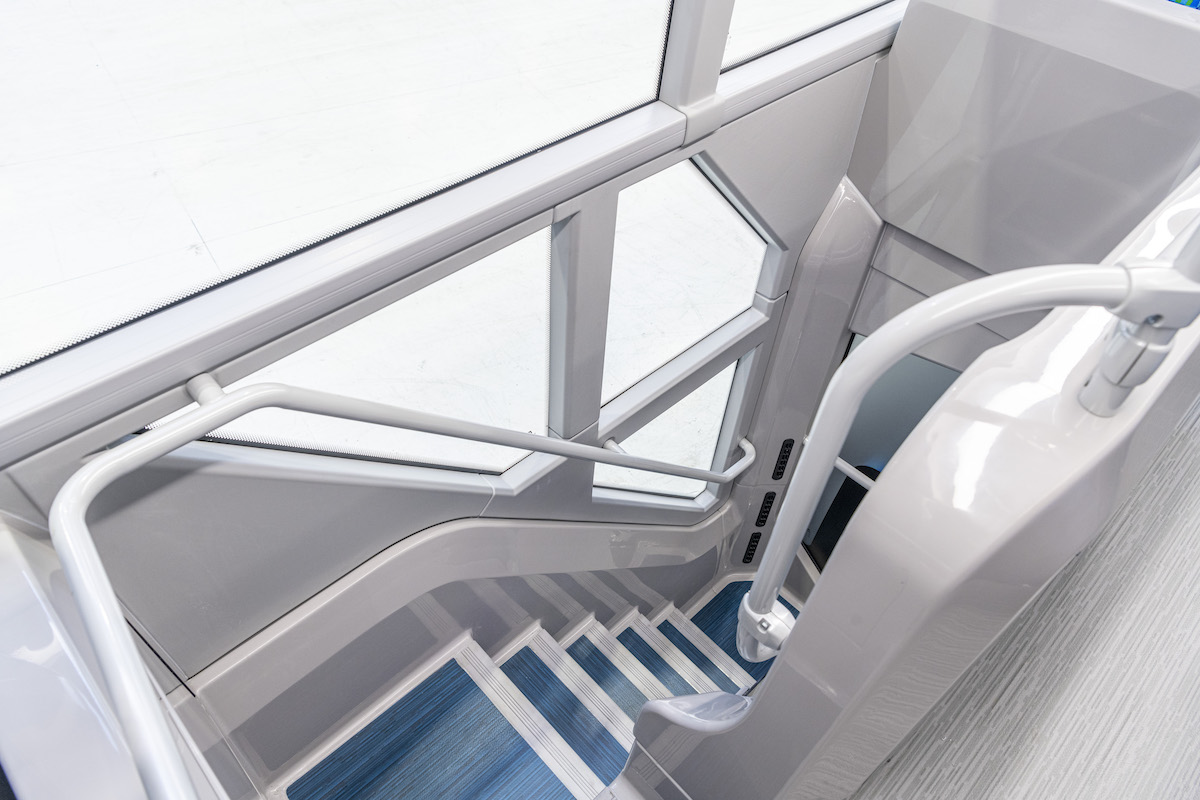

The battery packs are mounted within the chassis and rear of the vehicle as well as under the staircase of the Enviro400EV. Underfloor packs are mechanically isolated rather than directly bolted to the chassis, protecting them against external loads from twists and impacts that could cause premature failure.

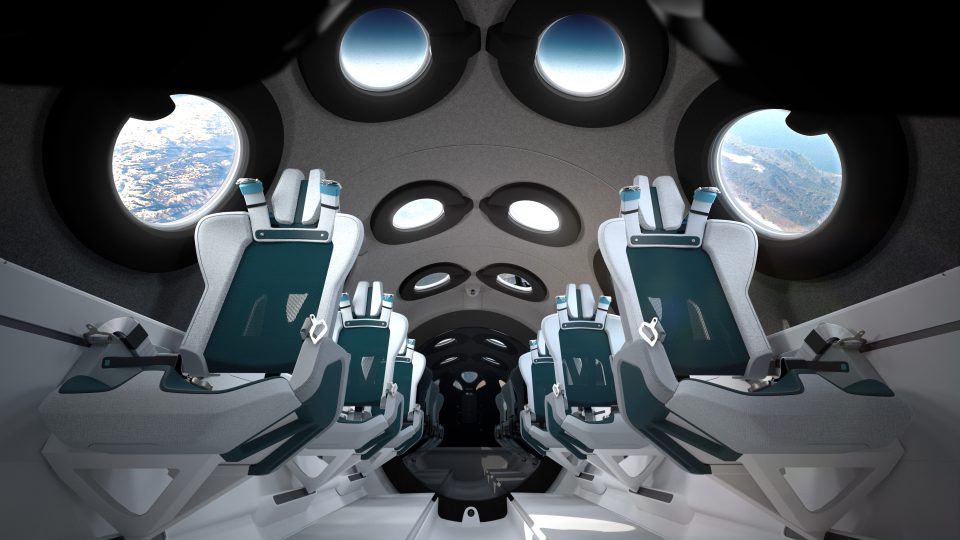

Inside the Enviro400EV

Access to the upper deck is via Alexander Dennis’s proven ‘squarecase’ with no angled steps, which offers an optimum combination of practicality and safety. Once upstairs, passengers will enjoy the view through full depth windows as well as a new panoramic upper front glass and optional skylights.

The working environment for bus drivers has also been improved with a new steering wheel, configurable dashboard display and improved heating, cooling and ventilation in the cab.

If replacement batteries are needed during the operational life of a vehicle, they will benefit from advances in battery capabilities without the need for vehicle modifications as pack dimensions and interfaces with the vehicle are standardised. Impact is already planning a future iteration of NMC batteries for Alexander Dennis that is expected to increase range even further.

Alexander Dennis President & Managing Director Paul Davies said: “The pace of change in our industry is rapid. We are proud of the progress we’ve made with electric buses over the last seven years, and our wide range of low-emission technologies before that. Now it’s time for us to take the next step and take zero-emission buses to the next level. We’re giving authorities and operators more choice, more flexibility and more value with our next generation of battery-electric buses.”

Alexander Dennis Group Engineering Director Chris Gall said: “Impact and Voith both stood out with their innovation and attention to detail when we chose the technology partners for our next generation of buses. Our engineers’ work has extended beyond finding the best solutions for our customers as we have spent the time to design future-proof vehicle interfaces that also protect these critical components so that authorities and operators’ investment will stand the test of time.”

Alexander Dennis new range in Larbert

The Enviro400EV will be assembled in Larbert, where Alexander Dennis has transformed its facility and overhauled its build process by introducing digital support tools and reducing the number of build stages to improve material, process and quality control.

These new working methods “will be progressively rolled out to all of the manufacturer’s sites including Scarborough, where the single deck production hall is being expanded along with the recently-announced addition of an off-site kitting and logistic facility. This will benefit production of the Enviro100EV, which takes advantage of Alexander Dennis’s global operations footprint before having its high-value components including axles, driveline, batteries, doors, seats and destinations fitted at Scarborough. Its chassis and body frame will be produced under direct supervision to Alexander Dennis designs by the company’s long-standing contract manufacturing partner in Zhuhai“, the manufacturer states.

Paul Davies commented: “We are introducing a split-build philosophy for our new ‘big small bus’ that is founded on the success of almost 4,200 buses we have assembled in Zhuhai over the last 15 years. Taking a more global view to our manufacturing strategy will allow us to increase our overall capacity and keep us competitive.”