Bodyshells in Czech Republic, e-buses in Mannheim, coaches in Neu-Ulm. The agreement between Daimler Buses and works council

Competition on the e-bus market pushes Daimler Buses to cut costs. Body shells production goes in Czech Republic, e-buses stays in Mannheim and coaches (plus intercity e-vehicles still to come) in Neu-Ulm. Agreement just reached between the Management of Daimler Buses and the General Works Council of EvoBus GmbH in order to ensure long-term competitiveness […]

Competition on the e-bus market pushes Daimler Buses to cut costs. Body shells production goes in Czech Republic, e-buses stays in Mannheim and coaches (plus intercity e-vehicles still to come) in Neu-Ulm.

Agreement just reached between the Management of Daimler Buses and the General Works Council of EvoBus GmbH in order to ensure long-term competitiveness and the German sites, as Daimler Truck states in a press note. The company says it “will implement various structural changes in order to permanently reduce the annual operating costs in Germany“.

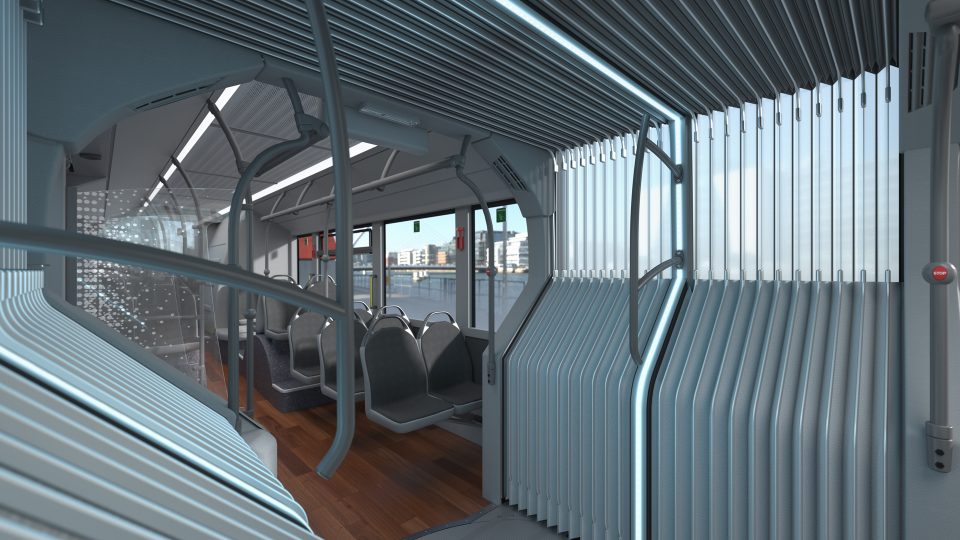

Mannheim will be the center of competence for electric city buses and, from 2024, will focus entirely on the production of fully electric city buses.

We have defined a clear roadmap for fully electric vehicles. However, there are many new competitors offering electric buses. This intensified market situation means that we have to position ourselves better in terms of production costs. This applies in particular to our German plants. We want to continue to offer our customers the best products at attractive conditions – and the target picture makes it possible

Till Oberwörder, CEO Daimler Buses

Bus bodyshell productions in Czech Republic

Among other things, the complete bus bodyshell construction for the Ligny-en-Barrois, Mannheim and Neu-Ulm plants will be carried out at the Holýšov site in the Czech Republic beginning in 2028.

In return, the General Works Council was able to achieve an extension of the existing employment protection for the employees of the EvoBus GmbH in Germany from 2024 until the end of 2033. This means that layoffs for operational reasons are excluded during this period.

Daimler Buses will also invest approximately 150 million euros in both German sites by the end of the decade.

Daimler Buses: there will be no capping of production in Germany

For the two sites in Mannheim and Neu-Ulm, the minimum size of the permanent workforce in production is set at 1,500 each. There will be no capping of production quantities in Germany, giving the Mannheim and Neu-Ulm plants the opportunity to benefit from future growth in demand.

All new Mercedes-Benz city buses and Setra coaches for the European market will be developed and launched at the Daimler Buses plants in Mannheim and Neu-Ulm in the future.

E-buses in Mannheim, coaches (and electric intercity buses) in Neu-Ulm

As mentioned above, Mannheim (3,300 employees) will be the center of competence for electric city buses and, from 2024, will focus entirely on the production of fully electric city buses. In addition, the plant is expanding component production.

Neu-Ulm (3,600 people) will remain the center of competence for coaches, and will continue to be the only location to manufacture Setra coaches. From the second half of the decade onward, fully electric intercity buses will also roll off the production line in Neu-Ulm and, from the end of the decade, coaches with battery electric and hydrogen-based fuel cell drives.

Daimler Buses: the need to cut production costs

Till Oberwörder, CEO Daimler Buses: “In intensive discussions with the Works Council, we have agreed on a target picture that is intended to ensure our long-term competitiveness. In this way, we are creating a long-term vision for our production sites in Mannheim and Neu-Ulm. We are and remain the only manufacturer that continues to produce city buses and coaches in Germany.”

“We have defined a clear roadmap for fully electric vehicles. However, there are many new competitors offering electric buses. This intensified market situation means that we have to position ourselves better in terms of production costs. This applies in particular to our German plants. We want to continue to offer our customers the best products at attractive conditions – and the target picture makes it possible,” Oberwörder continues.

Bruno Buschbacher, Chairman of the General Works Council of EvoBus GmbH belonging to Daimler Buses: “With the target picture for EvoBus, we have achieved a viable result. Both sides had to move in the negotiations. We have sustainably safeguarded our tradition-rich plants in Mannheim and Neu-Ulm and given our colleagues a reliable future perspective. Both plants will play a leading role in development and production in the future. Such a result was only possible because the colleagues from the two locations were united and worked together to defend their interests. As the General Works Council of EvoBus, we have to accept the relocation of the bus bodyshell construction abroad, because this is the only way for the company to regain the necessary competitiveness. Not conceding would only have brought more uncertainty for EvoBus in the coming years and would ultimately have meant a slow decline. We regret this step, but we have to face reality. Now it is the task of the management to make the necessary investments at the German sites, to ensure the agreed alternative employment and to lead EvoBus into a successful future,” says Buschbacher.