«Electric bus market is booming, we are ready». Interview with Akasol’s CEO Sven Schulz

October: the presentation of the new generation batteries, with amazing stated performances at Busworld Brussels. November: the reduction of the revenue forecast for 2019 due to «unplanned postponement of purchase quantities by our serial customers». Finally, December: the release of Jan-Sept 2019 revenues shows a 130% increase on the same period of 2018 (and a […]

October: the presentation of the new generation batteries, with amazing stated performances at Busworld Brussels. November: the reduction of the revenue forecast for 2019 due to «unplanned postponement of purchase quantities by our serial customers».

Finally, December: the release of Jan-Sept 2019 revenues shows a 130% increase on the same period of 2018 (and a +40 per cent on the entire 2018). But EBIT stands at – 2.7 million, higher than the -1 million of 2018. A loss «driven by important investments in preparing the organizational structure and production capacities for our further growth», as stated by Akasol CFO Carsten Bovenschen.

In a few word: lately it has been quite intense time for Akasol, at German-based battery supplier that made its debut on Frankfurt Stock Exchange in June 2018. Akasol’s origins date back to the ’90, to the experience of the Academic Solar Technology Group at Darmstadt Technical University. The student group developed the electric vehicle “Pinky”, which won the world championship for solar vehicles. Today Akasol is the electric bus battery supplier chosen by Mercedes and a leading manufacturer whose name is kept confidential by Akasol.

We met Akasol’s CEO Sven Schulz, who in in this interview shares with Sustainable Bus targets and achievements of the company. Outlining the trends of a market that is booming.

Sven Schulz: «80% of European bus sales will be electric by 2025»

Sven Schulz, which is the share of the bus related business on Akasol’s turnover?

«Today the serial business for buses and trucks covers the 60 percent of our turnover. Commercial vehicles business is catching up. Buses have been the first, but trucks are coming quickly. In five years, the electric truck business will become much bigger than the electric bus business».

It has been some year that we have been talking about the transition to electric buses in public transport. But volumes (except for China) are still small so far, although they are growing fast. When do you forecast big volumes to start in Europe?

«Market is going ahead, also from the regulatory point of view. I think it is growing very fast. This year, for the first time, nearly all the main manufacturers have electric buses available in their portfolio. In 2020-2021 we expect a dramatic increase of the volumes. By 2025, we expect that 80 per cent of all newly registered city buses in Europe will be electrified».

4 GWh Akasol batteries by 2022

How big is Akasol’s battery production capacity today and what is the targeted capacity?

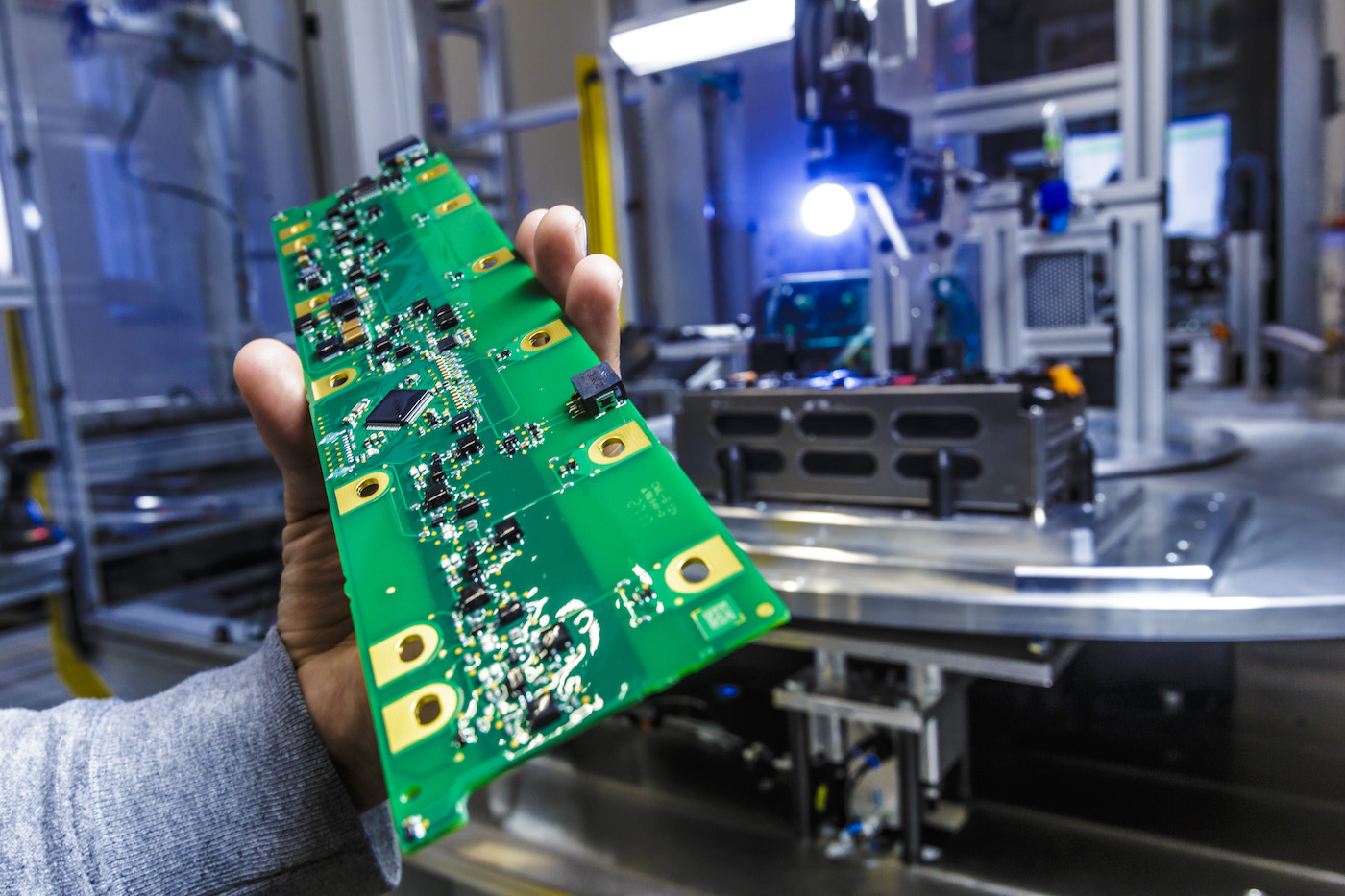

«Today our production capacity for battery systems is 300 MWh per year on three shifts in Germany. Enough for more than 1.000 ebuses. And we have a second production line being supplied in November. It will start operations in the first quarter of 2020 and ramp up during that year. At the end of 2020 our maximum capacity will thus reach 800 MWh for the Langen facility on three shifts.

Plus, we are currently building another production line in US and there we will reach 400 MWh in 2020. From 2021 we will have another serial production facility in our new headquarter in Darmstadt with more than 2.500 MWh capacity in combination with a second production line in the US for another 1.000 MWh in 2022 for our new ultra high energy battery system. Thus, the total production capacity will reach more than 4 GWh by 2022».

At Busworld you have launched a new battery system that is expected to double the battery capacity on board of a bus compared with today’s technology. With the expected increase in battery performances, fast charging infrastructures are expected to become less necessary in the future. Some manufacturers are even launching vehicles without fast charging option. How do you see this possible development?

«We think there won’t be a definitive solution. We have three major product versions, the ultra high energy, the ultra high power and the high power / high energy battery systems. The new ultra high energy battery system contains our entire know-how in the field of high-energy solutions for the commercial vehicle market and our technology is now capable of meeting the customer requirements associated with around 95 percent of range applications in combination with fast-charging capability. We can now provide what most customers ask for».

Sven Schulz: 2nd hand batteries in stationary solutions

Battery recyclability is one of the key issues when discussing about transition to electric drives. What would you do with batteries at the end of their life on board of the vehicle?

«If the battery is still good, we could install it in stationary solutions. One way is to have big ESS containers equipped with the old vehicle batteries to store renewable energies. The other solution we are working on is battery powered fast charging station where we can install around 220 kWh of new or second life batteries, to charge up to 4 passenger vehicles simultaneously with up to 220 kW. We developed this solution for a German car manufacturer, and it will be delivered soon».

NMC batteries are prevailing in European market. Chinese manufacturers (BYD for instance) use mainly LFP batteries, that are more widespread in that country. Which are the reasons for this difference?

«The main reason is that the Chinese government made the decision of LFP many years ago, therefore many Chinese manufacturers had to focus on LFP. In my view it will be a dead-end technology, because increasing the energy density will be limited. According to us, NMC will be the prevailing solution».

Solid-state batteries: not the solution (to date)

And what about the so called solid-state batteries?

«The benefit of solid-state batteries, theoretically, is that you can achieve high energy density. As of today, the so called solid-state batteries are at the same level of energy density as our systems, that will be deployed within 2020 and at least 30 per cent less than the new model AKASystem AKM CYC (showcased at Busworld and in production from 2021). With solid-state batteries today you can reach 440 kWh, with next generation of our NMC batteries you can install 600 kWh in the same space on an electric bus. We don’t see solid-state to be competitive in a technological level for a certain period of time. And we should also consider that the production for solid state is not industrialized yet. Therefore, the solid state systems are very expensive so far».

McKinsey released a report forecasting a decrease of the average price of battery prices from over 200 dollars per kwh in 2017 to less than 100 dollars per kWh in 2030. Which is your estimate?

«We see the trend in the same way. The price level that we can offer is becoming cheaper and cheaper. We managed to be very competitive with Chinese and American manufacturers. Plus, on the safety side, our battery system is setting standards, just like with our stainless steel housing to be compliant with our customer’s safety requirements».

Sven Schulz and the growing demand for hydrogen

This year we have seen a sort of comeback of hydrogen technology, with several manufacturer launching new products. You are launching a second generation hydrogen system. Do you see hydrogen buses to complement battery electric buses or to replace them in the long term?

«Hydrogen and battery-electric technologies are surely going to be complementary. We see that there is a growing demand on hydrogen fuel cell power trains as well. The fuel cell is a useful addition to fully electrically operated commercial vehicles, especially for long range requirements in commercial vehicles or trains and ships. That’s why we went into a project with hydrogen. We will power 50 fuel cell trucks with our battery systems for an Asian manufacturer, who is planning to build up to 1.000 more for a European customer, if the pilot fleet runs well. On the other hand, a weak point of hydrogen is the low efficiency rate, that is around 40 per cent».

Do you see possibility for intercity and coaches electrification?

«Our ultra high energy solution is perfect also for intercity buses and coaches. To date we are missing the will from manufacturer to make a coach like that. Maybe in 2 years the situation will be different».