MAN celebrates completion of works at battery manufacturing plant in Nuremberg

MAN Truck & Bus celebreates the completion of the new building for the large-scale production of batteries for fully electric trucks and buses at its Nuremberg site (announced in 2022), a few weeks after the delivery of the very first MAN eTruck to a customer. From April 2025, high-voltage batteries will be manufactured industrially in […]

MAN Truck & Bus celebreates the completion of the new building for the large-scale production of batteries for fully electric trucks and buses at its Nuremberg site (announced in 2022), a few weeks after the delivery of the very first MAN eTruck to a customer.

From April 2025, high-voltage batteries will be manufactured industrially in Nuremberg using state-of-the-art production methods on 17,000square metres. Up to 50,000 batteries per year will be built in an initial expansion phase, with goal of reachinbg up to 100,000 units.

The investment volume for the new building, including investments in logistics, infrastructure, buildings and production facilities, totals around 100 million euros.

MAN completes works for battery manufacturing

Currently, battery packs for MAN’s all-electric vehicles are already being produced in small series at the Nuremberg site, the OEM states. With the start of large series production, the small series production area will be gradually converted to the development of the next battery generation and the reconditioning of batteries. From April 2025, MAN says “the delivered modules will be inserted into battery layers in large series production. These layers will be stacked on top of each other to form the battery pack and then put through their paces”.

The installation of the first production systems has already begun. From April 2025, up to 50,000 batteries per year will be built in an initial expansion phase. Depending on how the market develops, this capacity is to be expanded to up to 100,000 high-voltage batteries by 2030, MAN states.

The Free State of Bavaria is also funding further development and research into battery technology with around 30 million euros. Among other things, this has enabled the integration of innovative laser welding cells. Laser welding is the most innovative, efficient and gentle production technology in battery module construction. With a powerful 8 kW disc laser, robot-guided optics and ultra-fine sensors, individual battery cells are electrically connected to each other with the highest precision and quality. Together with the Technical University (TU) of Munich, MAN is researching the further development of this technology, which will be used in a future generation of batteries.

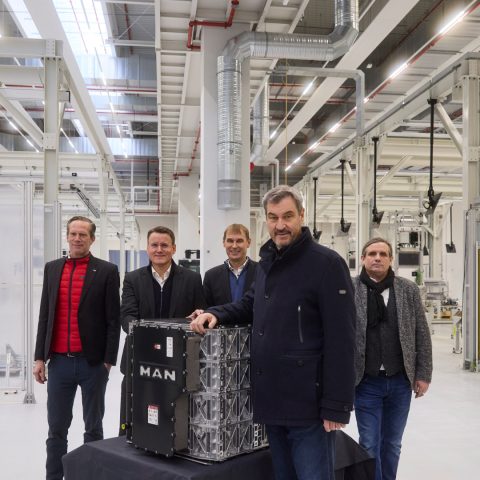

Guests at today’s topping-out ceremony included the Bavarian Minister President Markus Söder, Nuremberg’s Lord Mayor Marcus König, MAN Truck & Bus CEO Alexander Vlaskamp and the Chairman of the Works Council at MAN’s Nuremberg site Markus Wansch.

Alexander Vlaskamp states: “The drives of the future are being created in Nuremberg. Not only are we developing batteries here, but in a few months’ time we will also be using the latest technologies to mass-produce them. The topping-out ceremony is an important milestone for our company on the road to the major transformation towards electromobility. And it is also a clear commitment by MAN to Bavaria and Germany as a business location. This was made possible by close collaboration between the company, our works council and Bavarian politicians”.

Ingo Essel, Head of the MAN site in Nuremberg: “The entry into electromobility is a decisive step into the future for our site. We have decades of expertise in the development and production of engines and are now also ideally placed to establish ourselves as a centre of excellence for alternative drive technologies.’