Scania launches new electric powertrain for its e-bus platform, with four power options and gearbox

Scania is launching a new e-powertrain for its battery-electric bus offer, featuring four power options and an integrated two- or four-speed gearbox. A further battery option has been added, and a charging interface at the rear of the bus will quicken power uptake, Scania highlights, stressing that the new component is a compact drive device, […]

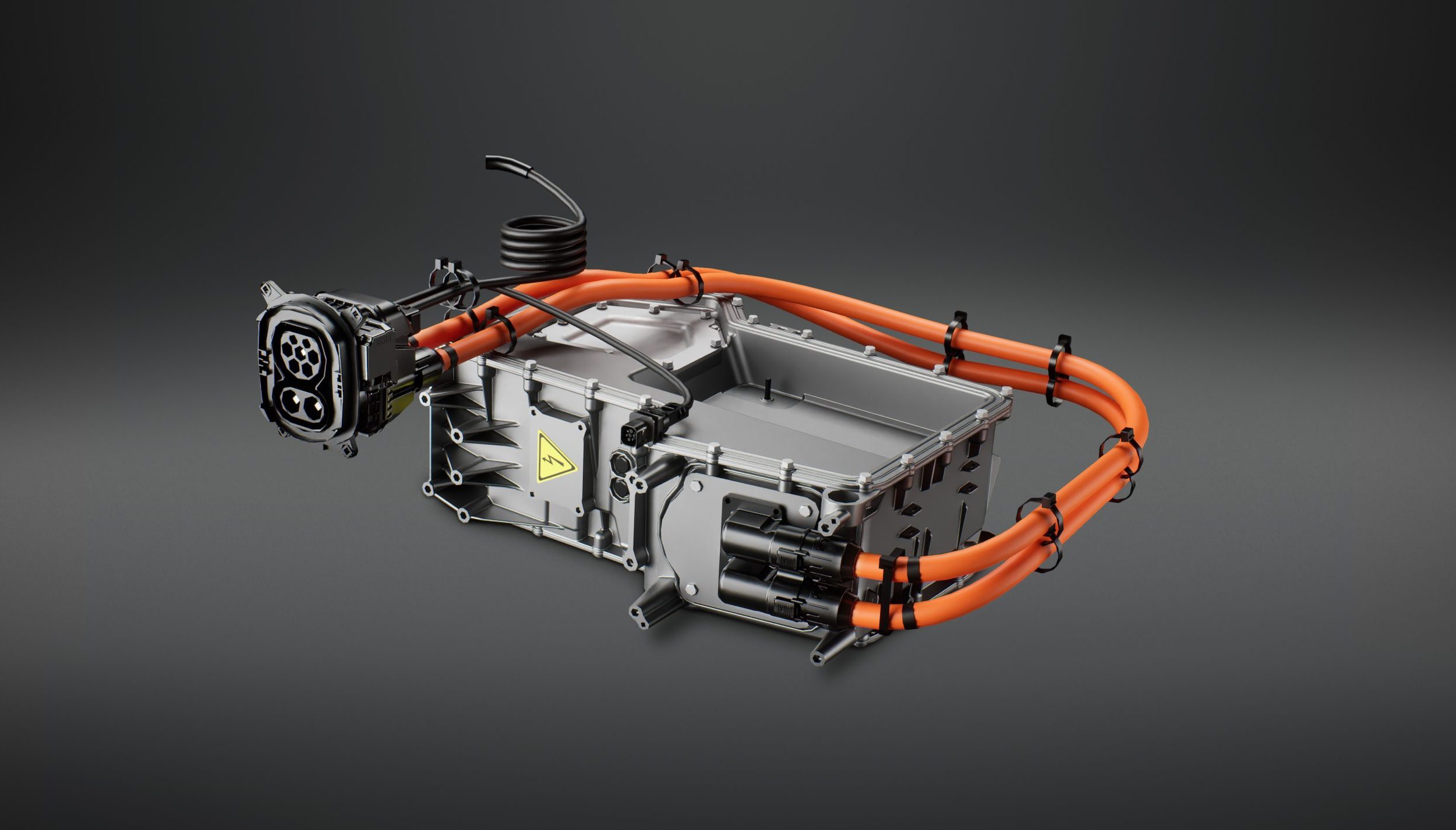

Scania is launching a new e-powertrain for its battery-electric bus offer, featuring four power options and an integrated two- or four-speed gearbox. A further battery option has been added, and a charging interface at the rear of the bus will quicken power uptake, Scania highlights, stressing that the new component is a compact drive device, consisting of electric motor, inverter, gearbox and oil system. Series production is planned to commence in Q3 of this year.

Scania has recently taken over Northvolt’s heavy-duty battery pack business. Following the decision to stop complete bus production in Europe adopted in mid 2023, the group has launched an electric bus model in partnership with Castrosua, a vehicle initially intended for the Spanish market. However, such e-bus chassis is not exclusive to Castrosua — it is designed to be adaptable and can be used with other bodybuilders, including Irizar. The Scania – Higer Fencer, in the meanwhile, started commercialization in Germany and Austria.

Focus on Scania new powertrain for electric buses

The group states that customers can now choose between four different power options: 240 kW, 270 kW, 300 kW and 330 kW.

Delving into more specific details, Anna Ställberg, Head of Urban Solutions for People Transport Solutions at Scania Group, explains to Sustainable Bus that “The four power options come with different gearbox variants, as follows: 240 kW with 2-speed gearbox; 270, 300 and 330 kW with 4-speed gearbox. Further, the new e-machine provides excellent powertrain torque, with the 240 kW power option and 2-speed gearbox offering 5,100 Nm in the first gear and 2,200 Nm in the second gear. And with the other power options, using the 4-speed gearbox, customers can expect the torque to be even higher”.

Ställberg adds that the new e-machine has been developed jointly within the Traton group, but on the bus side, it is currently only being integrated in Scania products.

Scania is also introducing a three-battery pack option with 312 kWh of installed energy, as well as a second charging interface at the rear of its buses, which gives customers the chance to specify by themselves or, with Scania’s help set up the buses according to their particular needs.

“In terms of battery cell suppliers, while work has been accelerated, Scania´s strategy has always been to have more than one supplier. We have secured future supplies of battery cells and will share additional technical information further along, but both the Northvolt- and alternative supplier cells are of NMC chemistry“, Anna Ställberg adds.

The rear interface is available for higher charging power of 325 kW with up to 500 A, compared with the current front charging position’s 130 kW with up to 200 A of charging power, Scania says.

This is how Scania describes the working process of its new electric powertrain for buses: “The motor transforms the electric energy stored in the battery into mechanical energy, creating torque, while the inverter transforms the direct current voltage from the battery into a three-phase alternating current. This converted power is then fed to the electric machine, enabling it to effectively control and adjust both speed and torque. There is also a single oil system with two oil pumps, which cools the e-machine and lubricates the gearbox”.

“We know that bus operators face the push-pull effect of responding to emission regulations while striving to meet the specific demands of electric operations. Power needs, flexibility, charging time, energy efficiency and operational range are some of the key factors,” says Anna Ställberg, Head of Urban Solutions for People Transport Solutions at Scania Group. “The new e-machine, battery and charging options have been developed and are being introduced with our customers’ challenges in mind, and respond to both their and our sustainability goals.”